307132

7

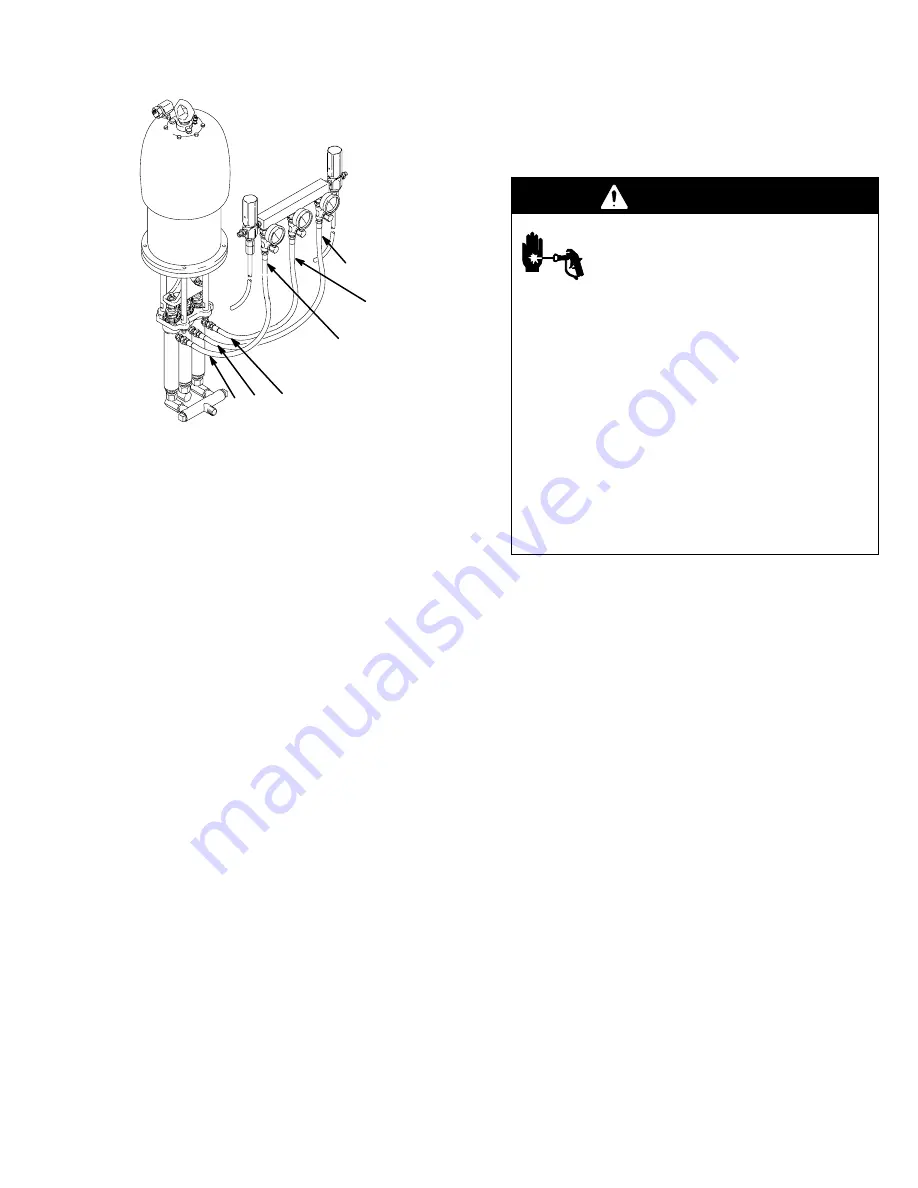

Installation

TI0645

Ensure hoses are routed correctly

during installation with three dis-

placement pump models.

A

A

B

A

A

B

NOTE:

See page 22 for accessories mentioned in this

section.

In the following instructions, the base fluid will always

be called part A and the catalyst will be called part B.

With three displacement pump models, always use the

two outer displacement pumps to supply part A and

the middle displacement pump to supply part B.

Mount pump to suit the type of installation planned.

Accessory wall mounting bracket is shown on page 22,

pump dimensional drawing and mounting hole layout

are shown on page 24. When mounting pump on wall,

be sure the wall is strong enough to support the pump

and other equipment, plus any stress developed when

equipment is operating. Drill three 3/16 in. diameter

holes in mounting bracket as shown on page 24. Using

screws (43 or 56), screw manifold (49 or 62) onto

bracket.

Connect part A inlet hose to 3/4 npt inlet of manifold on

three displacement pump models, or to 3/4 npt inlet of

left hand displacement pump on two displacement

pump models. Connect part B inlet hose to 3/4 npt

swivel union inlet of center displacement pump mod-

els.

System Accessories

Install the accessories in the order shown in the

Typi-

cal installations

on pages 5 and 6. Working up-

stream from the pump inlet, install a pump runaway

valve (B) to shut off the air to the pump if the pump

accelerates beyond the pre-adjusted setting. A pump

which runs too fast can be seriously damaged.

Next, install an air line lubricator (C) for automatic air

motor lubrication, a bleed-type master air valve (A) to

relieve air trapped between the valve and the pump, an

air regulator (D) to control pump speed, and an air filter

(E) to remove harmful dirt and moisture from the com-

pressed air supply.

Install a fluid drain valve (G) at each fluid outlet to re-

lieve pressure in the system. Be sure the valve is

pointed downward.

WARNING

INJECTION HAZARD

Two accessories, the bleed-type master

air valve (A) and the fluid drain valve (G)

are required for your system to reduce

the risk of serious injury from moving parts, fluid

injection, or splashing when shutting off the pump.

The bleed-type air valve relieves air trapped be-

tween the valve and the pump, after the pump is

shut off. Trapped air can cause the pump to cycle

unexpectedly and result in serious injury if you are

adjusting or repairing the pump.

The fluid drain valve helps relieve fluid pressure in

the displacement pump, hose and gun when shut-

ting off the pump. Triggering the gun to relieve

pressure may not be sufficient, especially if there is

a clog in the hose, gun/dispensing valve, or tip/

nozzle.

Install and connect feed pumps, solvent pump, mixer,

etc. See

Typical installations

on pages 5 and 6

and separate component instructions.

Feed Systems

Material supply must be pressure fed into each propor-

tioning cylinder. If materials require heating they can

be heated in the supply feed as well as the outbound

side of the pumps. Material supply is critical to proper

proportioner operation. Material must fill the proportion-

er cylinders on their upstroke totally to elimiate a “div-

ing” of the cylinders on the top change–over. This “div-

ing” will also be seen as a pressure drop at the change

over. This will cause an off ratio condition.

Ensure your feed systems are designed to supply

twice the volume used by each componet. This supply

pump pressure should never exceed 25% of the pro-

protioner output pressure.

Example:

4:1 proportioner. 2.0 gpm output, 1000 psi.

4:1 ratio at 2.0 gpm = 1.5gpm of “A” component and

1/2 (.5) gpm of component “B”.

“A” feed pump needs to have a 4 gpm capacity

at a max of 250psi.

B" feed pump needs to be at least 1 gpm at

250 psi max.

Review your feed systems with your Graco Distributor.

Summary of Contents for BULLDOG HYDRA-CAT 208958

Page 17: ...307132 17 Notes...

Page 23: ...307132 23 Notes...