English

•

Owner´s manual

32

Adjustment

1) Loosen the clutch rod and unscrew the lock nut.

2) Loosen the adjusting nut to release the adjusting screw

and adjust to the desired extension. Play with the extension

of the rope, until the rod of the adjusting screw is depressed,

until the belt does not slip and is released when the clutch

lever is released.

(1) Adjusting screw rod

(2) Clamping nut

2

1

3) If the belt continues to slip after adjustment by the above methods, loosen the four locknuts loosen the

four motor locknuts and move the motor backwards until the belt stops slipping. Make sure that when

the clutch lever is released, the clutch lever stops acting.

4) If the belt slippage problem cannot be solved after the above adjustment, please replace the belt.

Braking devices

Inspection

1) Start the engine and shift the gear to forward.

2) Depress the clutch bar and observe if the conveyor operates normally. Stop the conveyor on a 30

degree slope and observe if the conveyor moves downward.

3) If there is any abnormal situation, repair it immediately.

WARNING:

Any problems with the brake should be adjusted immediately.

Adjustment

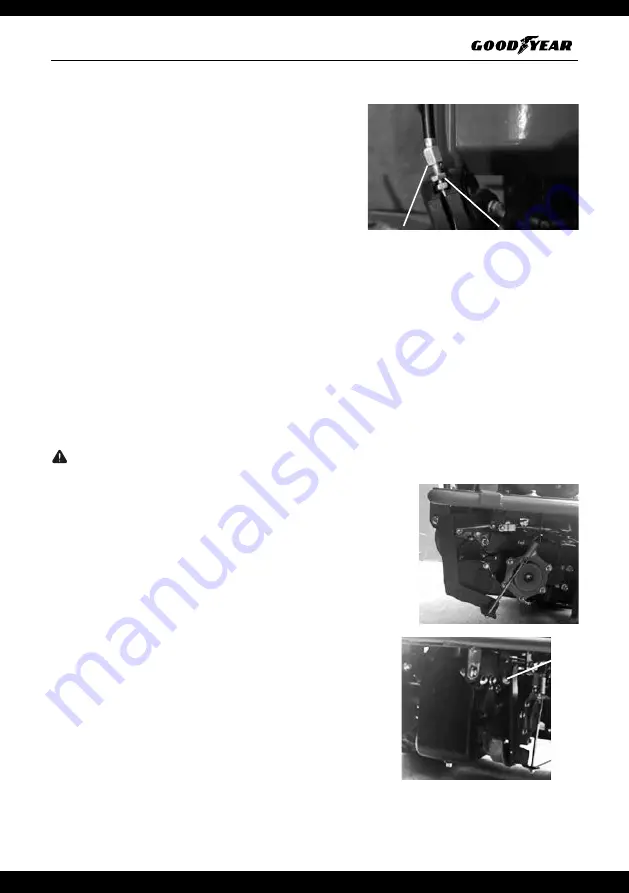

1) When the conveyor moving speed is slow or the belt

is intact, but the conveyor cannot walk, please press the

engine to adjust.

- As shown in the figure on the right, turn the adjusting nut 1

and tighten it until the end of the screw.

- If you still cannot solve the problem, please contact the

distributor or the technicians to solve the problem.

2) When the conveyor stops on the ramp and moves down,

please release the clutch and stop the motor and then follow

these steps:

- As shown in the figure on the right, turn the adjusting nut 2

to increase the spring tension so that it stops slipping.

- If you still cannot solve the problem, please replace the

brake pads.

(1) Adjusting nut 1

(2) Adjusting nut 2

1

2