6

www.goodmanmfg.com

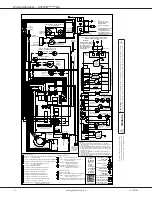

SS-GCEC96

SS-GCEC96

www.goodmanmfg.com

7

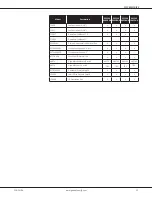

Airflow Data — GCEC960603BN

Notes

•

All furnaces ship as high speed for cooling. Installer must adjust blower speed as needed.

•

For most jobs, about 400 CFM per ton when cooling is desirable.

•

INSTALLATION IS TO BE ADJUSTED TO OBTAIN TEMPERATURE RISE WITHIN THE RANGE SPECIFIED ON THE RATING PLATE.

COOLING

Dipswitch Setting:

S1-1 S1-2 S1-3

Static

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

Tstat Call

CFM

CFM

CFM

CFM

CFM

CFM

CFM

CFM

**OFF OFF OFF

Ylo

1149

1104

1057

1017

963

918

865

822

Y

1236

1189

1149

1101

1066

1017

969

928

ON OFF OFF

Ylo

782

629

547

469

396

333

N/A

N/A

Y

1149

1104

1057

1017

963

918

865

822

ON ON OFF

Ylo

782

629

547

469

396

333

N/A

N/A

Y

1236

1189

1149

1101

1066

1017

969

928

OFF ON OFF^

Ylo

1149

1104

1057

1017

963

918

865

822

Y

894

846

780

720

660

603

554

505

OFF OFF ON^

Ylo

1149

1104

1057

1017

963

918

865

822

Y

1328

1287

1249

1215

1170

1131

1085

1046

OFF ON ON

Ylo

782

629

547

469

396

333

N/A

N/A

Y

894

846

780

720

660

603

554

505

ON OFF ON

Ylo

1328

1287

1249

1215

1170

1131

1085

1046

Y

1236

1189

1149

1101

1066

1017

969

928

ON ON ON^

Ylo

1328

1287

1249

1215

1170

1131

1085

1046

Y

782

629

547

469

396

333

N/A

N/A

CONTINUOUS FAN

Dipswitch Setting:

S2-2 S2-3 S2-4

Static

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

Tstat Call

CFM

CFM

CFM

CFM

CFM

CFM

CFM

CFM

**OFF OFF OFF

G

894

846

780

720

660

603

554

505

ON OFF OFF

G

1328

1287

1249

1215

1170

1131

1085

1046

ON ON OFF

G

782

629

547

469

396

333

290

251

OFF ON OFF

G

1149

1104

1057

1017

963

918

865

822

OFF OFF ON

G

1236

1189

1149

1101

1066

1017

969

928

OFF ON ON

G

894

846

780

720

660

603

554

505

ON OFF ON

G

894

846

780

720

660

603

554

505

ON ON ON

G

894

846

780

720

660

603

554

505

HEATING

Dipswitch Setting:

S1-4 S2-1

Static

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

CFM

Rise

CFM

Rise

CFM

Rise

CFM

Rise

CFM

Rise

CFM

CFM

CFM

**OFF OFF

W1

894

41

846

44

780

47

720

51

660

56

603

554

505

W2

1328

40

1287

41

1249

42

1215

43

1170

45

1131

1085

1046

ON OFF

W1

782

47

629

NA

547

N/A

469

N/A

396

N/A

N/A

N/A

N/A

W2

1328

40

1287

41

1249

42

1215

43

1170

45

1131

1085

1046

ON ON

W1

782

47

629

NA

547

N/A

469

N/A

396

N/A

N/A

N/A

N/A

W2

1149

46

1104

48

1057

50

1017

52

963

55

918

865

822

OFF ON

W1

1149

32

1104

33

1057

35

1017

36

963

38

918

865

822

W2

1236

43

1189

44

1149

46

1101

48

1066

50

1017

969

928

** Factory Default

SINGLE STAGE COOLING^

*NOT RECOMMENDED