8

www.goodmanmfg.com

SS-GCEC96

SS-GCEC96

www.goodmanmfg.com

9

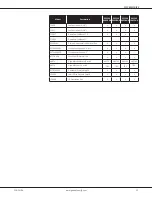

Airflow Data — GCEC961005CN

Notes

•

All furnaces ship as high speed for cooling. Installer must adjust blower speed as needed.

•

For most jobs, about 400 CFM per ton when cooling is desirable.

•

INSTALLATION IS TO BE ADJUSTED TO OBTAIN TEMPERATURE RISE WITHIN THE RANGE SPECIFIED ON THE RATING PLATE.

COOLING

Dipswitch Setting:

S1-1 S1-2 S1-3

Static

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

Tstat Call

CFM

CFM

CFM

CFM

CFM

CFM

CFM

CFM

**OFF OFF OFF

Ylo

1637

1577

1528

1467

1410

1369

1307

1256

Y

2069

2009

1978

1932

1923

1876

1834

1773

ON OFF OFF

Ylo

1477

1422

1364

1301

1244

1190

1135

1078

Y

1637

1577

1528

1467

1410

1369

1307

1256

ON ON OFF

Ylo

1477

1422

1364

1301

1244

1190

1135

1078

Y

2069

2009

1978

1932

1923

1876

1834

1773

OFF ON OFF^

Ylo

1637

1577

1528

1467

1410

1369

1307

1256

Y

1300

1234

1175

1109

1052

992

928

866

OFF OFF ON^

Ylo

1637

1577

1528

1467

1410

1369

1307

1256

Y

1866

1817

1774

1729

1684

1637

1593

1552

OFF ON ON

Ylo

1477

1422

1364

1301

1244

1190

1135

1078

Y

1300

1234

1175

1109

1052

992

928

866

ON OFF ON

Ylo

1866

1817

1774

1729

1684

1637

1593

1552

Y

2069

2009

1978

1932

1923

1876

1834

1773

ON ON ON^

Ylo

1866

1817

1774

1729

1684

1637

1593

1552

Y

1477

1422

1364

1301

1244

1190

1135

1078

CONTINUOUS FAN

Dipswitch Setting:

S2-2 S2-3 S2-4

Static

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

Tstat Call

CFM

CFM

CFM

CFM

CFM

CFM

CFM

CFM

**OFF OFF OFF

G

1300

1234

1175

1109

1052

992

928

866

ON OFF OFF

G

1866

1817

1774

1729

1684

1637

1593

1552

ON ON OFF

G

1477

1422

1364

1301

1244

1190

1135

1078

OFF ON OFF

G

1637

1577

1528

1467

1410

1369

1307

1256

OFF OFF ON

G

2069

2009

1978

1932

1923

1876

1834

1773

OFF ON ON

G

1300

1234

1175

1109

1052

992

928

866

ON OFF ON

G

1300

1234

1175

1109

1052

992

928

866

ON ON ON

G

1300

1234

1175

1109

1052

992

928

866

HEATING

Dipswitch Setting:

S1-4 S2-1

Static

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

CFM

Rise

CFM

Rise

CFM

Rise

CFM

Rise

CFM

Rise

CFM

CFM

CFM

**OFF OFF

W1

1300

47

1234

50

1175

52

1109

56

1052

59

992

928

866

W2

1866

47

1817

48

1774

50

1729

51

1684

52

1637

1593

1552

ON OFF

W1

1477

42

1422

43

1364

45

1301

47

1244

49

1190

1135

1078

W2

1866

47

1817

48

1774

50

1729

51

1684

52

1637

1593

1552

ON ON

W1

1477

42

1422

43

1364

45

1301

47

1244

49

1190

1135

1078

W2

1637

54

1577

56

1528

58

1467

60

1410

62

1369

1307

1256

OFF ON

W1

1637

38

1577

39

1528

40

1467

42

1410

44

1369

1307

1256

W2

2069

43

2009

44

1978

44

1932

46

1923

46

1876

1834

1773

** Factory Default

SINGLE STAGE COOLING^

*NOT RECOMMENDED