10

www.goodmanmfg.com

SS-GCEC96

SS-GCEC96

www.goodmanmfg.com

11

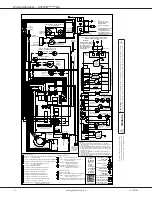

Wiring Diagram — GCEC96******AA

Wiring

is

su

bject

to

cha

ng

e.

Alw

ay

s

re

fer

to

the

wiring

diagr

am

on

the

unit

for

the

mos

t up-t

o-da

te

wiring.

⚠

W

arning

High

Volt

age:

Disc

onnect

all

po

w

er

be

for

e

ser

vicing

or

ins

talling

this

unit.

Multiple

po

w

er

sour

ces

ma

y

be

pr

esen

t.

Failur

e

to

do

so

ma

y

cause

pr

operty

damag

e,

per

sonal

injur

y,

or

dea

th.

⚡

GN

GND

COLOR CODES:

GN GREEN

RD RED

GY GRAY

PU PURPLE

PK PINK

BK BLACK

BL BLUE

WH WHITE

BR BROWN

YL YELLOW

OR ORANGE

GND

BK

RD

GN

GN

24

VAC

115

VAC

GND

GR

D

BK

YLO Y W1 W2 R G C TWIN

N.E.C. CLASS 2 WIRE

0140F02481-A

BR

PK

GY

OR

GN

BL

YL

S1

BK

HUM

X-

FM

R

L1

CI

RC-

H

EAC

-H

5

2

1

4

3

24 V 3 A

FUSE

NEUTRAL

DIAGNOSTIC

LED'S

5 CI

RCUI

T CO

NNE

CT

O

R

10

6

3

4

5

2

7

11

1

12

8

9

FRONT COVER

PRESSURE

SWITCH

NO

C

FUSE 3 A

MICRO

TO

PS2 (2)

TR (9)

G

HI

C

TH (5)

24

V T

HER

M

O

ST

AT

C

O

NN

EC

TIO

NS N

.E.

C. C

LASS 2

W

IR

E

VALVE

GAS

W2

TRANSFORMER

HLI (6)

Y2

Y1

HLO (11)

GND (4)

O

MVL (7)

NO

W1

C

R

CONTROLS

AUTO RESET AUXILIARY LIMIT

LIMIT CONTROLS

MANUAL RESET ROLLOUT

PRESS. SWTICH

HIGH FIRE

C

SWITCH

LOW FIRE PRESS

MVH (1)

DEHUM

GND

PS1 (12)

LIMIT CONTROL

AUTO RESET PRIMARY

24 VAC

NO

PM

MVC (8)

INTEGRATED CONTROL MODULE

C

BLWR

AIR

INDOOR

CIRCULATOR

R

TO

MICRO

TO

TO

+VDC

EAC

HUMIDIFIER

ID

NEUTRAL

WIRING TO UNIT

L

INT

EG

RA

TE

D CO

NT

RO

L M

O

DUL

E

HOT SURFACE

GND

BLWR

NEUTRAL

WARNING:

GROUNDED.

OVERCURRENT PROTECTION DEVICE

MUST BE PROPERLY

SWITCH

NEUTRAL

ELECTRONIC

AIR

IGN

IND HI

DISCONNECT

FS

POLARIZED AND

NEUTRAL

LINE

NEUTRAL

JUNCTION BOX

BLWR

IND LO

N

INDOOR

AIR CLEANER

HUM

DOOR

NEUTRAL

INT

EG

RA

TE

D CO

NT

RO

L M

O

DUL

E

TO 115VAC/ 1Ø /60 HZ POWER SUPPLY WITH

115 VAC

HUM-OUT

IGNITER

CIRCULATOR

BEFORE SERVICING.

FLAME SENSOR

DISCONNECT POWER

LINE

GND

T1 T2

OR

BR

BK

W

H

WH WH

WH

PU

GY

YL

OR

BR

PK

RD

WH

BK

PU

GY

BR

OR

RD

OR

BL

RD

WH

WH

LINE

NO

LIMIT CONTROL

AUXILIARY

AUTO RESET

PK

WARNING:DISCONNECT

TRA

NS

FO

RM

ER

40 V

A

PU

GY

N

NO

G

C

SWITCH

PRESSURE

LOW FIRE

SENSOR

FLAME

PRESSURE SWITCH

FRONT COVER

C

TO UNIT MUST BE

BL

RD

AND GROUNDED.

1

JUNC

TIO

N B

O

X

WH

SWITCH (PRESS.)

FIELD SPLICE

FIELD GND

3

GN

BL

BR

WH

NO

LIMIT CONTROL

AUTO RESET PRIMARY

WH

1

OR

30 kBTU AND 40 kBTU)

CONTROLS (SINGLE CONTROL ON

MANUAL RESET ROLLOUT LIMIT

WH

L

PU

GY

BK

SWITCH ASSEMBLY

ID BLOWER TWO-STAGE PRESSURE

OR

WH

SERVICING. WIRING

EQUIPMENT GND

INTERNAL TO

SWITCH

PRESSURE

HIGH FIRE

PROT. DEVICE

INTEGRATED CONTROL

PK

PU

PLUG CONNECTION

L

N

BK

C

DOOR OPEN)

(OPEN WHEN

DOOR SWITCH

COMPARTMENT

BLOWER

SWITCH (TEMP.)

GND

1

BLOWER

CIRCULATOR

JUNCTION

OR

40 VA

Ø /60 HZ

DISCONNECT

(WHITE RODGERS)

GAS VALVE

TWO STAGE

OVERCURRENT

CONNECTOR

2 CIRCUIT

LOW VOLTAGE (24V)

YL

GND

WH

CHA

SS

IS

G

RO

UND

2

3

IGNITER

SURFACE

HOT

2

YL

PU

C

2

C

BLOWER

DRAFT

INDUCED

BK

PM

BK

BLOWER COMPARTMENT

115 VAC/ 1

OVERCURRENT

BK

HARNESS

ECM MTR

HI

TERMINAL

OR

POWER BEFORE

IGNITER

RD

BK

TO

RD

POWER SUPPLY WITH

BURNER COMPARTMENT

PROTECTION DEVICE

PROPERLY POLARIZED

RD BK

OR

BL

LOW VOLTAGE FIELD

HI VOLTAGE (115V)

HI VOLTAGE FIELD

RAPID

= TWINNING ERROR

STEADY ON = INTERNAL GV ERROR, MICRO AND FREQUENCY CHECK

1 FLASH = FLAME SENSED WHEN NO FLAME SHOULD BE PRESENT

4 FLASHES = OPEN LIMIT SWITCH

0

4

3

2

1

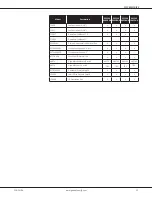

RED LED FLASH CODE

2 FLASHES = PRESSURE SWITCH STUCK CLOSED/INDUCER ERROR

3 FLASHES = 1ST STAGE PRESSURE SWITCH STUCK

OPEN/INDUCER ERROR

5 FLASHES = OPEN ROLLOUT/OPEN FUSE DETECTED

6 FLASHES = PRESSURE SWITCH CYCLE LOCKOUT

7 FLASHES = EXTERNAL LOCKOUT (RETRIES)

9

6

5

7

8

8 FLASHES = EXTERNAL LOCKOUT (RECYCLES)

9 F GROUNDING OR REVERSED POLARITY

10 FLASHES = GAS FLOW WITH NO CALL FOR HEAT

11 FLASHES = LIMIT SWITCH OPEN-BLOWER FAILURE

12 FLASHES = IGNITOR RELAY FAILURE

11

10

12

3 DOUBLE FLASHES = 2ND STAGE PRESSURE SWITCH

STUCK OPEN/INDUCER ERROR

3 FLASHES = W2 PRESENT WITH NO W1

2 FLASHES = NORMAL OPERATION WITH

CALL FOR 2ND STAGE HEAT

1 FLASH = NORMAL OPERATION WITH CALL FOR

1ST STAGE HEAT (W1)

2

4

3

1

4 FLASHES = Y PRESENT WITH NO G CALL, YLO

PRESENT WITH NO G CALL

AMBER LED FLASH CODE

RAPID = LOW FLAME SENSE CURRENT

RAPID = NORMAL OPERATION WITH CALL FOR FAN (G)

STEADY ON = STANDBY

1 FLASH = NORMAL OPERATION WITH CALL FOR

LOW STAGE COOL (YLO + G)

0

2

1

GREEN LED FLASH CODE

2 FLASHES = NORMAL OPERATION WITH CALL FOR HIGH

STAGE COOL/ OR SINGLE STAGE COOLING (Y + G)

0

1. SET HEAT ANTICIPATOR ON ROOM THERMOSTAT AT 0.7 AMPS.

NOTES:

$

2. MANUFACTURER'S SPECIFIED REPLACEMENT PARTS MUST BE USED

WHEN SERVICING.

MUST BE REPLACED IT MUST BE REPLACED WITH WIRING MATERIAL

HAVING A TEMPERATURE RATING OF AT LEAST 105 C. USE COPPER

CONDUCTORS ONLY.

4. UNIT MUST BE PERMANENTLY GROUNDED AND CONFORM TO N.E.C.

AND LOCAL CODES.

5. TO RECALL THE LAST 6 FAULTS, MOST RECENT TO LEAST RECENT,

DEPRESS SWITCH FOR MORE THAN 2 SECONDS WHILE IN STANDBY

(NO THERMOSTAT INPUTS)

3. IF ANY OF THE ORIGINAL WIRE AS SUPPLIED WITH THE FURNACE

S3

S2

T5

T3 T4

RD

CO

M

BK