12

Visit our website at http://www.globalhobby.com or for Customer Service at http://globalservices.globalhobby.com

❑

When you are satisfied that the stabilizer is square to the wing, use a pencil to draw a couple of marks on each side of

the front of the stabilizer where it and the fuselage sides meet, then use a couple of pieces of masking tape to hold the

stabilizer firmly in place and aligned.

❑

With the stabilizer held firmly in place, look from the front

of the airplane at both the wing and the stabilizer. When

aligned properly, the stabilizer should be parallel to the wing.

☞

If the stabilizer is out of alignment, remove it and use 220

grit sandpaper with a sanding block to sand down the higher

side of the stabilizer mounting slot, then reinstall the stabilizer

and check the alignment once more. Repeat this procedure

until you are satisfied with the alignment.

❑

With the stabilizer properly aligned, use a pencil to draw a line on each side of the stabilizer where it meets the

fuselage sides. Do this on both the top and the bottom.

❑

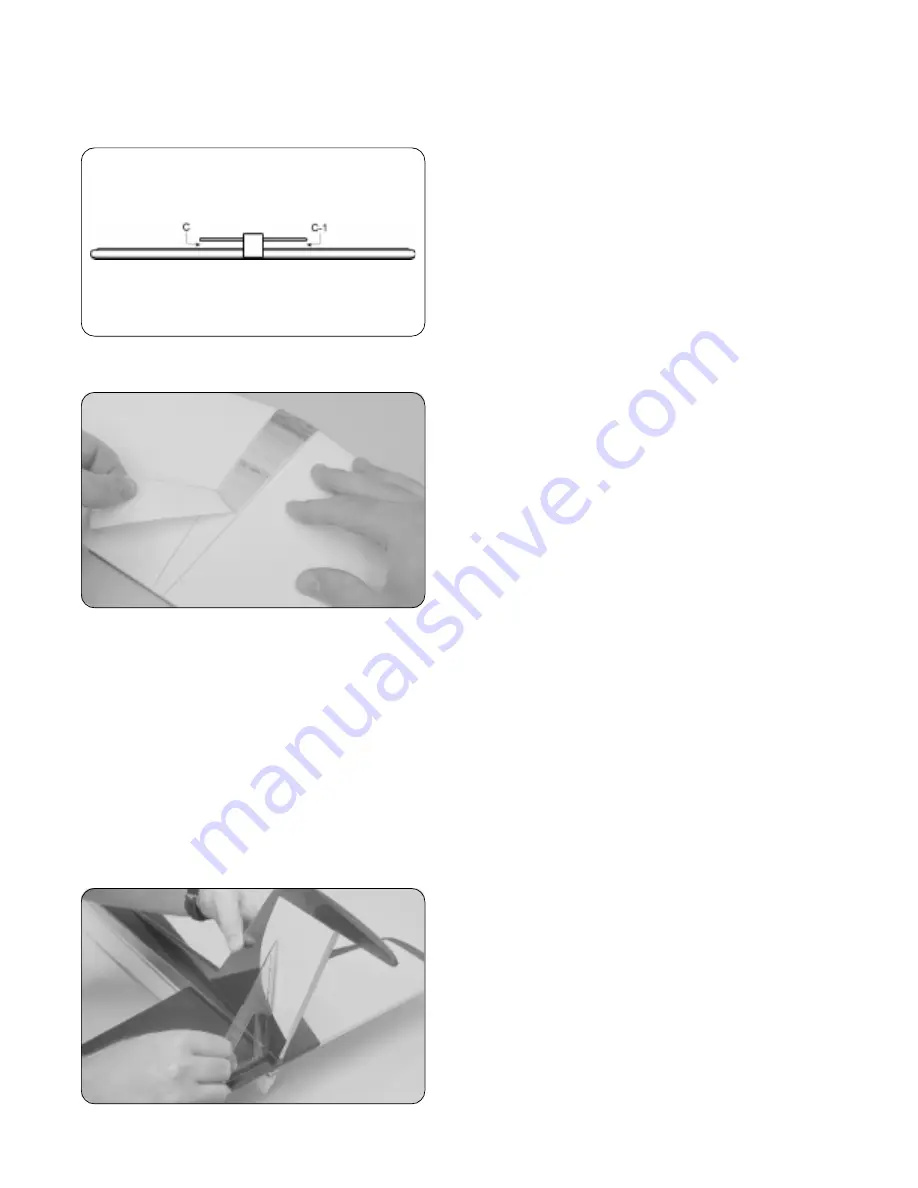

Remove the stabilizer. Using a modeling knife, carefully

cut away and remove the covering material from between the

lines you drew. Do this on both the top and the bottom.

WARNING

When cutting through the covering to remove it,

cut with only enough pressure to cut through only the covering

itself. Cutting down into the balsa structure could weaken the

stabilizer and cause it to fail during flight.

❑

Mix and apply a generous amount of 30 minute epoxy to

ONLY the top and bottom

gluing surfaces of the stabilizer.

IMPORTANT

Because the stabilizer has to slide in place through the fuselage, apply epoxy only to the stabilizer. This will

prevent the epoxy from spreading over the entire length of one half of the stabilizer when you slide it into place.

❑

Slide the stabilizer back into place and realign it, double-checking all of your measurements once more before the

epoxy sets up. Quickly remove the excess epoxy and use pieces of masking tape to hold the stabilizer in place until the

epoxy has fully cured.

❑

After the epoxy has fully cured, remove the masking tape and look closely at the glue joint. If there are any gaps

between the stabilizer and the fuselage, fill them using 30 minute epoxy for added strength. Again, before the epoxy sets

up, remove any excess using a paper towel and rubbing alcohol.

Step 3: Aligning & Installing the Vertical Stabilizer

❑

Remove the rudder and hinges from the vertical stabilizer

and set them aside for now.

❑

Push the vertical stabilizer down into its mounting slot.

To align it properly, the stabilizer should be even with the

back edge of the fuselage and it should be pushed down

firmly. The dorsal fin should also be aligned with the middle

of the fuselage.

❑

Using a builder's triangle, check to make sure that the

vertical stabilizer is aligned 90º to the horizontal stabilizer.