ENGLISH

12

SETTING DADO CUTS

This saw can be used to cut grooves (dados) in the workpiece, rather than

cut right through. The saw head is lowered only part way and while held in

that position, a cut is made.

1.

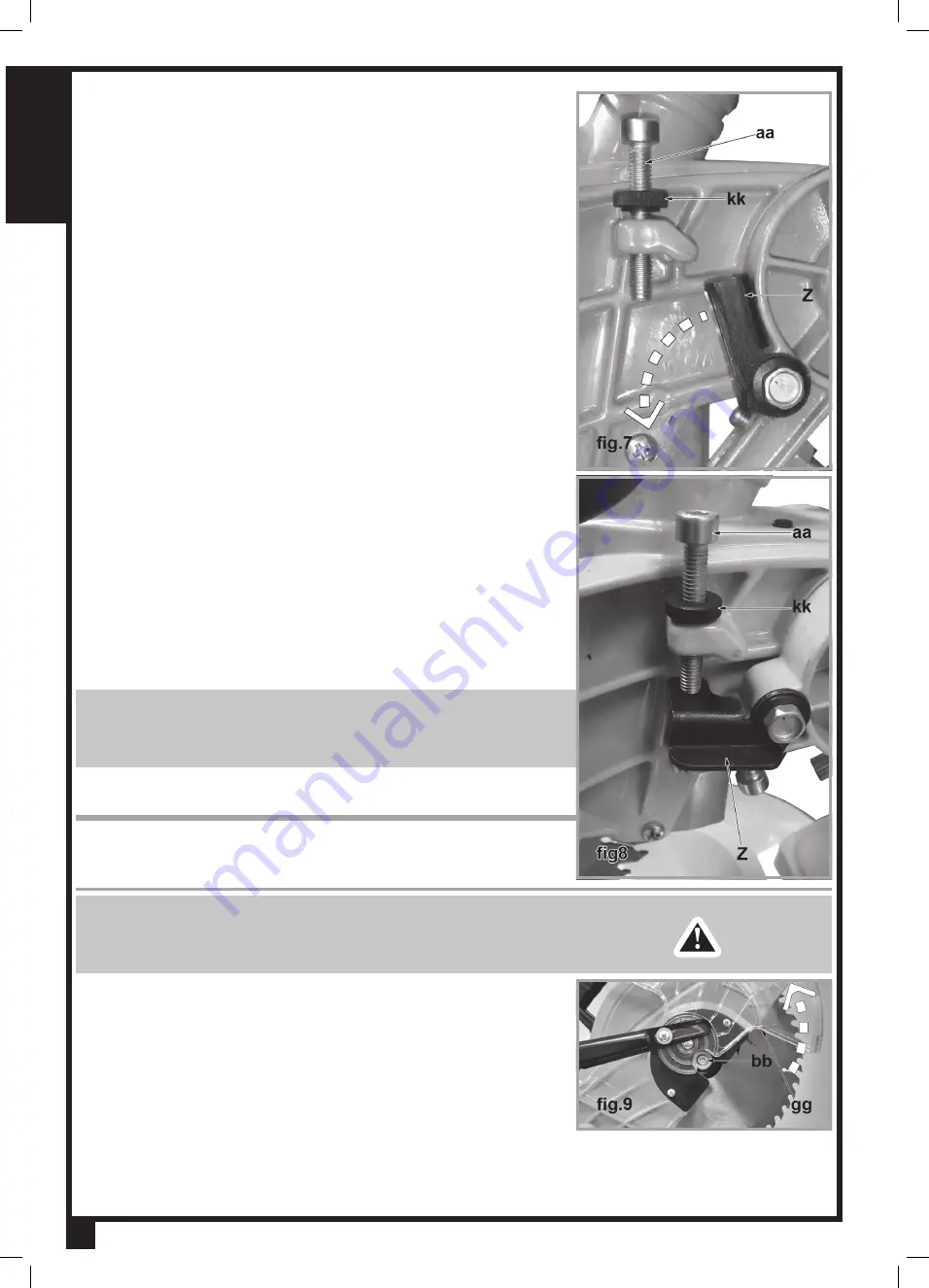

This dado depth is engaged when the dado stopper plate (Z, fig 7 & 8) is

swung down and engages the dado depth adjust screw (da, fig.7 & 8).

2. To set the depth to which the blade will cut during this operation, pull the

dado stopper plate down from its resting position. (fig.8)

3. Push the handle down completely, to its lowest position, and notice that

now the dado depth adjustment screw is what limits the downward travel

of the sawhead.

4. Turn the dado depth adjustment screw with a 5 mm hex wrench so that

the saw blade teeth at their lowest point are above the table surface at a

height corresponding with the desired depth of the dado.

5.

Tighten the knurled locking nut (kk, fig.7 & 8) on the shank of the dado

depth adjustment screw to lock its setting.

6. Test the depth of the dado by making a trial cut in a piece of scrap

material.

7. Adjust as necessary.

NOTE:

This saw is

not

designed to be used with a true dado blade. In

order to make wide dado cuts, use a standard (1/8” thick) blade and

make multiple adjacent cuts at the set depth or make a cut on each side

and remove the material in between manually.

MAINTENANCE

MOUNTING AND REMOVING THE

BLADE

WARNING:

Before replacing the saw blade always unplug the tool.

Make sure that the spindle speed diameter and saw blade bore match.

Only use sharp and undamaged saw blades. Cracked or bent saw

blades must be replaced immediately.

1. Lock the head of the machine in its highest, upright position.

2. From the left side of the saw, rotate the lower saw blade guard (gg,

fig.9) counter-clockwise until the hex socket head blade bolt (bb, fig.9)

that holds the blade is exposed.

Summary of Contents for MS3003

Page 16: ...ENGLISH 16...