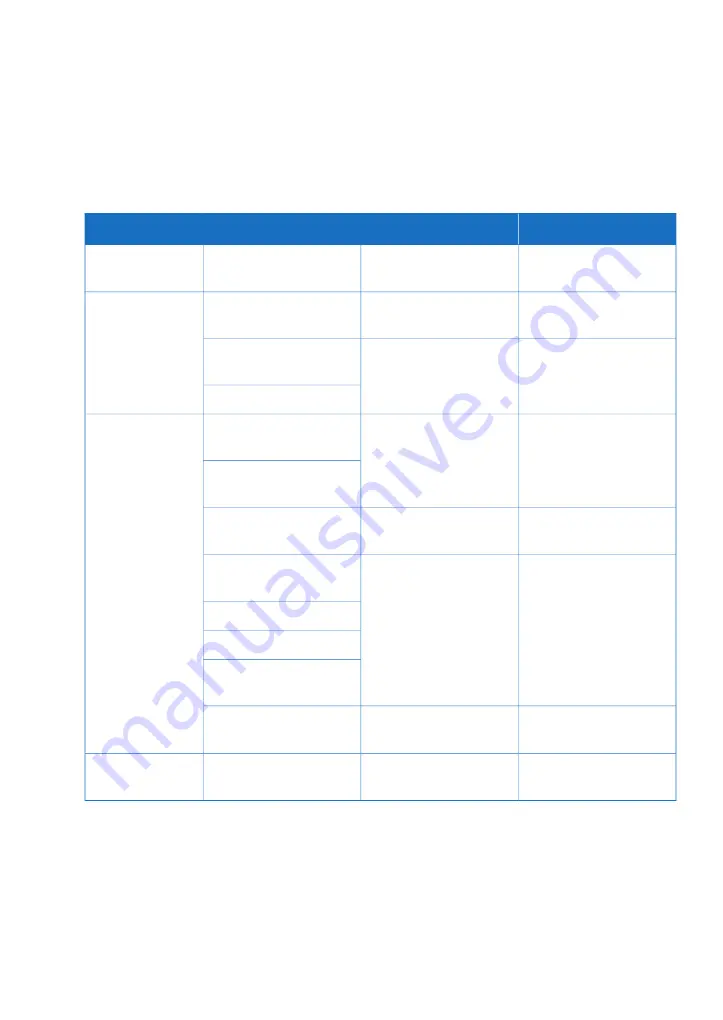

User maintenance schedule

The following table describes maintenance activities that must be scheduled by customer

personnel. All maintenance that is not described in this manual must be performed by

a GE service engineer.

Reference

Performed by

Activity

Frequency

Section 8.5 Cleaning, on

page 257

Operator

Clean the system

Weekly

See the manufacturer's

manual.

Properly trained person-

nel

Change the TCU filter

Annually

Contact your GE represen-

tative.

GE service engineer

Change the I/O Cabinet

vent filter

Verify agitator alignment

If anything abnormal is

found, contact your GE

representative for ser-

vice.

Properly trained person-

nel

Inspect cables and con-

nectors

Annually and after

system relocation

Inspect hinges and han-

dles

Inspect jacking bolts, on

page 259

Properly trained person-

nel

Inspect jacking bolts

If anything abnormal is

found, contact your GE

representative for ser-

vice.

Properly trained person-

nel

Inspect pressure relief

assembly

Inspect pump heads

Inspect the I/O Cabinet

Inspect vent and drain

valves

Verify weight monitoring

accuracy, on page 261

Properly trained person-

nel

Verify weight monitoring

functionality

Contact your GE represen-

tative.

GE service engineer

Verify agitator speed ac-

curacy

1

As needed

1

If the instrument is used less than 12 times a year, the verification can be made annually.

Xcellerex XDM 50-1000, XDUO 100-1000 mixers Operating Instructions 29251615 AD

251

8 Maintenance

8.2 Maintenance schedules

Summary of Contents for Xcellerex XDM Series

Page 2: ...Page intentionally left blank...

Page 6: ...Page intentionally left blank...

Page 320: ...Page intentionally left blank...

Page 321: ...Page intentionally left blank...