Backpulse Tank Pressure Check

Using the Digital Air Pressure Gauge, check the

Backpulse Tank pressure. If it is not at the correct pressure

(Approximately 35 psi for most installations;

Refer to the

Service Tag for the actual reading), adjust the pressure

using an air pump or compressor. Refer to Step 3 of the

System installation

section under

E. inSTallaTiOn inSTrUCTiOnS

for guidance.

2

G. annUal MainTEnanCE

To extend the life of the System’s membrane, maintenance

procedures are recommended on a minimum of an annual

basis. A Service Kit is required, including an Integrity

Tester and other necessary tools, to perform the Annual

Maintenance. A

Homespring™ Qualified Technician

must perform all maintenance including the annual

Integrity Test as required as part of the 5 year limited

prorated System warranty. If the

Homespring™ Qualified

Technician

determines that the System has a high degree

of debris causing a reduction in the flowrate, the number

of maintenance visits per year may be increased to ensure

that the System stays within operational limits, and to

ensure the limited prorated warranty protection remains in

effect.

annual Maintenance Procedure

Transmembrane Pressure Test

The first step will be to perform a “pre-cleaning” trans-

membrane pressure test. To perform this test, follow

the

steps in the

Transmembrane Pressure Test

section under

f. COMMiSSiOninG

. Thi

s test will be performed prior to

the cleaning and again following the Integrity Test. The

results of these tests are to be recorded on the Service

Tag.

If the Inlet Valve is upstream of the External Prefilter,

change the External Prefilter follo

wing guidelines

in the

Surface Water Option Kit installation

section under

E. inSTallaTiOn inSTrUCTiOnS

to install a new

External Prefilter cartridge before beginning the Membrane

Cleaning.

1

3

membrane cleaning

WARNING!

Disposable protective gloves must be worn during

maintenance of the System to protect your hands.

At the end of the procedure, wash your hands

thoroughly with soap and water. Do not reuse the

gloves. Dispose of the gloves in the garbage.

complete Paperwork

The following documents are shipped with the System:

Owner’s Manual

Congratulations letter

Installation Checklist

Service Tag

Warranty Card

Pipe Labels

• Complete all info on the Service Tag and hang from

System Cap.

• Complete and return the Installation/Registration

Checklist, ensure that all fields are complete, including the

homeowner’s signature.

•

Record the model number on page 2 of the Owner’s

Manual

for future reference.

final flush by Homeowner

Have the homeowner continue to run a cold water tap for

60 minutes. This is required to meet NSF drinking water

standards and to remove residual chlorine. The homeowner

may notice chlorine taste/smell when a tap is first opened

for a day or two following the cleaning procedure.

Transmembrane Pressure (TMP) Test

The TMP test measures the pressure drop across

the membrane. This is the pressure change that the

homeowner will observe as a result of the filtering

process. The TMP is tracked during the life of the System

and is used to determine the condition of the System

membrane. As the membrane fouls, the TMP will increase.

2

With a nearby tap running with a high flow rate,

read the two Pressure Gauges and subtract the Outlet

pressure from the Inlet pressure. The resulting value is the

TMP. Record the value on the Service Tag.

When a pump/pressure tank is in use, use the following

inlet pressure to determine TMP:

1

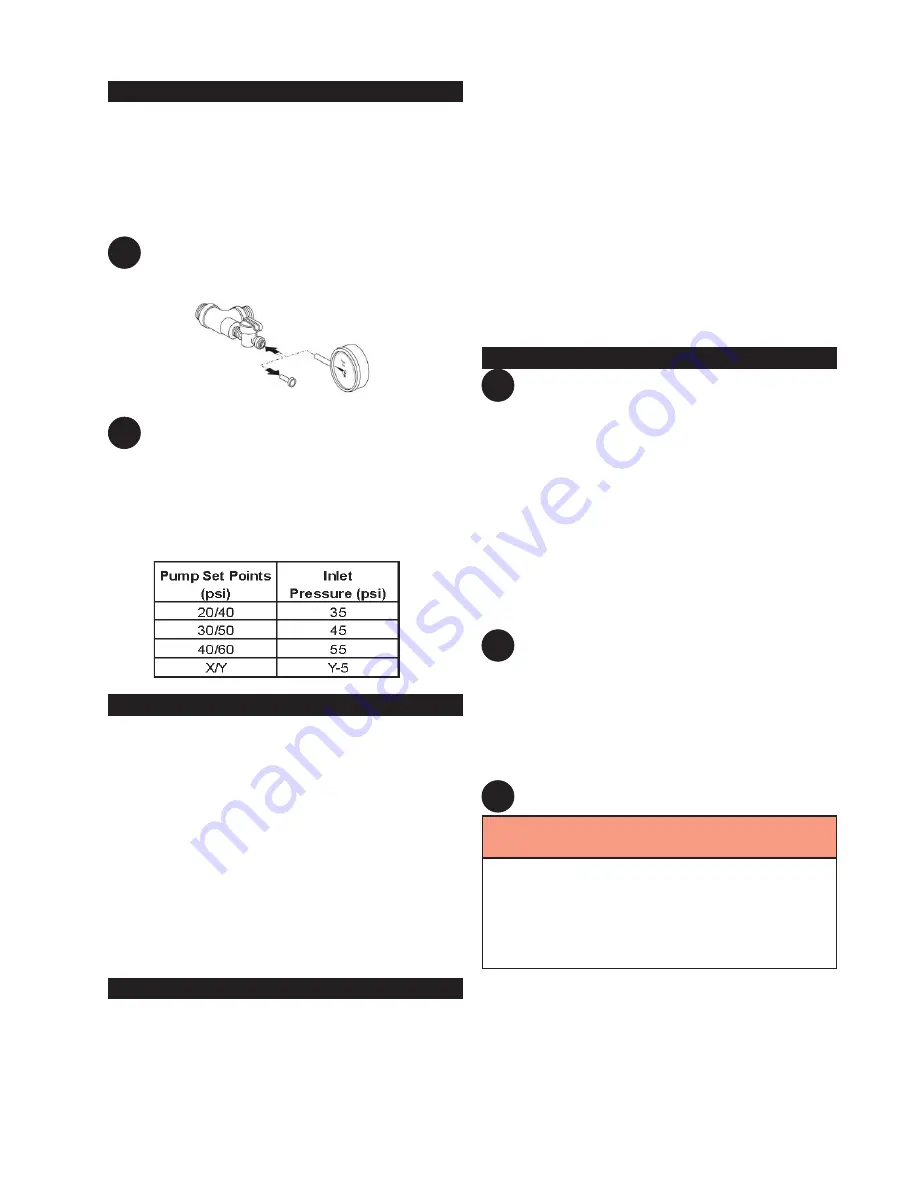

Insert a Pressure Gauge into each of the Inlet and

Outlet Mini Ball Valves and open the valves.

fiGUrE 46

For installations excluding ground water installations,

clean the membrane following the steps

in the

cleaning

section under

f. COMMiSSiOninG

with the following

exceptions. In Step

3,

after the System Cap is removed,

wipe the System Cap out with a clean, soft cloth, remove

the O-ring carefully, wipe the O-ring with a clean cloth,

check the O-ring for damage or wear, apply a very small

amount of DOW CORNING 111 silicone lubricant on the

23