Advanced EnerVista 750/760 Setup features

750/760 Quick Reference Guide

27

•

Event Recorder

: The event recorder captures contextual data associated with the last

512 events, listed in chronological order from most recent to the oldest.

•

Oscillography

: The oscillography waveform traces and digital states provide a visual

display of power system and relay operation data captured during specific triggered

events.

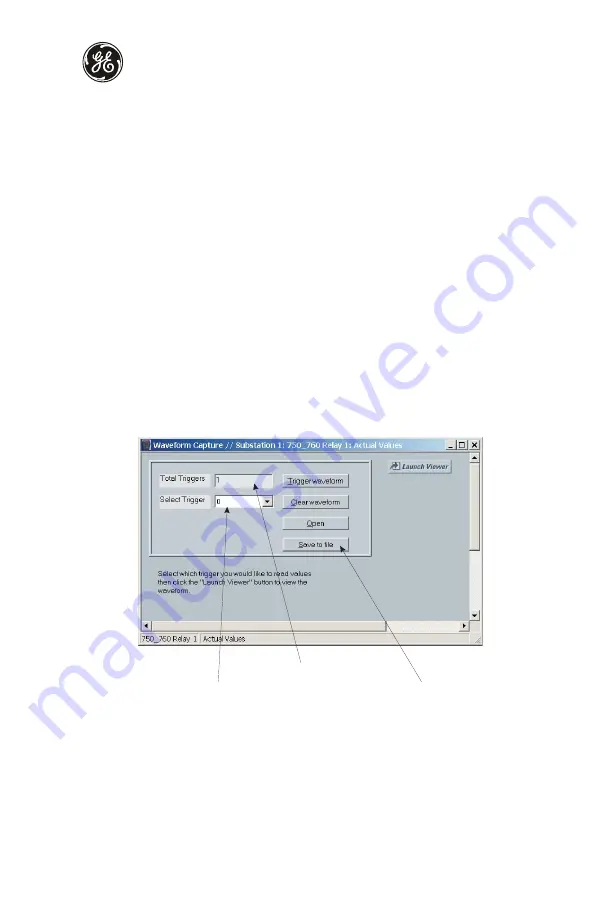

Waveform capture (trace memory)

The EnerVista 750/760 Setup software can be used to capture waveforms (or view trace

memory) from the 750/760 relay at the instance of a trip. A maximum of 512 cycles can be

captured and the trigger point can be adjusted to anywhere within the set cycles. A

maximum of 16 waveforms can be buffered (stored) with the buffer/cycle trade-off.

The following waveforms can be captured:

•

Phase A, B, and C currents (

I

a

,

I

b

, and

I

c

)

•

Ground and Sensitive ground currents (

I

g

and

I

sg

)

•

Phase A-N, B-N, and C-N voltages (

V

a

,

V

b

, and

V

c

)

•

Digital data for output relays and contact input states.

The following procedure describes the waveform capture feature.

1.

With EnerVista 750/760 Setup running and communications established, select the

Actual > Waveform Capture

menu item to open the waveform capture setup

window:

Click on

Trigger Waveform

to trigger a waveform capture.

The waveform file numbering starts with the number zero in the 750/760; therefore,

the maximum trigger number will always be one less then the total number triggers

available.

2.

Click on the

Save to File

button to save the selected waveform to the local PC. A new

window will appear requesting for file name and path. The file is saved as a CSV

(comma delimited values) file, which can be viewed and manipulated with compatible

third-party software.

Number of available files

Files to be saved or viewed

Save waveform to a file

Summary of Contents for 750

Page 2: ......

Page 39: ...Application example 750 760 Quick Reference Guide 35 Figure 17 Typical three line diagram...

Page 41: ...Application example 750 760 Quick Reference Guide 37 Figure 19 Typical control diagram...

Page 42: ...Application example 38 750 760 Quick Reference Guide Figure 20 Typical breaker control diagram...

Page 43: ...Application example 750 760 Quick Reference Guide 39 Figure 21 Typical relay control diagram...