© ANITA

MP03200

EN_180810

31

5

Broken thread

Wrong threading of upper

thread

Make correct threading

Wrong position of needle

Set correct position of needle

Damaged needle

Exchange needle

Wrong tension of upper or lower

thread

Re-

install correct thread

tension

Wrong tension and rigidity of

thread tension spring

Re-

install correct tension and

rigidity of thread tension

spring

Damage of hook upper spring

Exchange hook upper spring

and check if theh hook is not

mechanically damaged

6

Thread skips or falls

off

the needle eye

Bent needle

Exchange the needle

Thread thickness is not in

correspondence with needle size

Exchange the needle

Wrong position of needle

Re-

install correct needle

position

Wrong timing of motion

between needle and hook

Re-

adjust correct timing

between needle and hook

Too big clearance between

needle and hook

Re-

adjust correct clearance

between needle and hook

Wrong tension of thread take

-up

spring

Adjust correct tension of the

spring

7

Wrong function of

thread breakage

detector

Thread take

-

up spring is not well

linked with thread sensor plate

Clean the thread take

-up

spring and the sensor plate

and adjust the correct mutual

position

The wire of thread sensor plate

is not well linked

Check the correct wiring

8

Bad quality of thread

tension

Tension of needle thread is not

sufficient

Adjust correct tension of

needle thread

Tension of bobbin thread is not

sufficient

Adjust correct tension of

bobbin thread

Wrong timing of the motion

between needle and hook

Adjust

correct timing of the

motion between needle and

hook

9

Trimming error occurs

The cross tension between

movable and fixed knife is loose

Adjust the tension of the

fixed knife

Blades of movable or fixed knife

are damaged or worn

-out

Replace movable or fixed

knife

Wrong trimming speed or speed

of the knife

Adjust the trimming speed or

speed of the knife

- see

chap.8

www.garudan.cz

Summary of Contents for GPS/X-3525 Series

Page 5: ...ANITA MP03200EN_180810 5 2 DESCRIPTION Fig 1 w w w g a r u d a n c z...

Page 32: ......

Page 36: ...ANITA MP03200EN_180822 4 A FRAME AND MACHINE BODY PARTS w w w g a r u d a n c z...

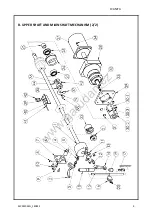

Page 38: ...ANITA MP03200EN_180822 6 B UPPER SHAFT AND MAIN SHAFT MECHANISM 1 2 w w w g a r u d a n c z...

Page 42: ...ANITA MP03200EN_180822 10 C PRESSER FOOT MECHANISM 1 2 w w w g a r u d a n c z...

Page 44: ...ANITA MP03200EN_180822 12 C PRESSER FOOT MECHANISM 2 2 w w w g a r u d a n c z...

Page 46: ...ANITA MP03200EN_180822 14 D LOWER SHAFT AND SHUTTLE MECHANISM 1 2 w w w g a r u d a n c z...

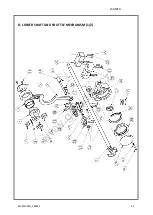

Page 48: ...ANITA MP03200EN_180822 16 D LOWER SHAFT AND SHUTTLE MECHANISM 2 2 w w w g a r u d a n c z...

Page 50: ...ANITA MP03200EN_180822 18 E THREAD TRIMMING MECHANISM 1 2 w w w g a r u d a n c z...

Page 54: ...ANITA MP03200EN_180822 22 G X MOVING MECHANISM 1 2 w w w g a r u d a n c z...

Page 56: ...ANITA MP03200EN_180822 24 G X MOVING MECHANISM 2 2 w w w g a r u d a n c z...

Page 58: ...ANITA MP03200EN_180822 26 I FEED FRAME MECHANISM 1 2 w w w g a r u d a n c z...

Page 60: ...ANITA MP03200EN_180822 28 I FEED FRAME MECHANISM 2 2 w w w g a r u d a n c z...

Page 62: ...ANITA MP03200EN_180822 30 I2 FEED FRAME FOR CUSTOMER DESIGN w w w g a r u d a n c z...

Page 64: ...ANITA MP03200EN_180822 32 J THREAD TENSION MECHANISM w w w g a r u d a n c z...

Page 66: ...ANITA MP03200EN_180822 34 K BOBBIN WINDER AND HAND PULLEY w w w g a r u d a n c z...

Page 68: ...ANITA MP03200EN_180822 36 L STAND AND TABLE w w w g a r u d a n c z...

Page 70: ...ANITA MP03200EN_180822 38 M LUBRICATION PARTS w w w g a r u d a n c z...

Page 72: ...ANITA MP03200EN_180822 40 N AIR CONTROL PARTS w w w g a r u d a n c z...

Page 74: ...ANITA MP03200EN_180822 42 Q OPERATION UNIT AND THREAD STAND w w w g a r u d a n c z...

Page 76: ...ANITA MP03200EN_180822 44 R CONTROL BOX w w w g a r u d a n c z...

Page 78: ...ANITA MP03200EN_180822 46 S OPTION w w w g a r u d a n c z...