© ANITA

MP03200

EN_180810

30

9 TROUBLESHOOTING

No. Type of the problem

Cause of the problem

Solution

1

Error of control

system or machine

driving unit

Error message on the display of

needle motor driver for X or Y

axis

Inform manufacturer about

the type of error message

Fuse is short

-

cut

Check fuses in the

switchboard

Switched

-

off circuit breaker

Check position of the circuit

breaker in the switchboard

Error message on the machine

display

Act in accordance with type

of error message and

information from the

operation manual

2

Wrong needle upper

stop position

Wrong setting of parameter for

needle upper stop position angle

or parameter of reverse angle

Check correct setting of

following parameters:

25 Reverse angle

26 Up stop position angle

35 Reverse angle

before

wiper

Wrong position of needle motor

sensor or sensor plate

Check position of needle

motor sensor plate and the

sensor function

Fault of needle motor or motor

driver

Exchange motor for needle

driving mechanism or

respective driver in the

switchboard

3

Wrong position of

feed frame

Loosen screws leading to slipping

of driving toothed wheels of X

and Y axis

Check if screws of feed frame

driving wheel mechanism are

properly tightened

Wrong fixing of the sewn

product

Correct proper fixing of the

sewn material inside the

template

Loss of X

-

or Y

-

motor steps

Lower the sewing speed and

check if there are not any

mechanical obstacles

preventing motor or feed

frame from fluent movement

4

Fault of needle

Damaged needle (bent, broken

or worn

-

out)

Exchange the needle

Wrong position of needle

Re-

install correct positron of

the needle

Contact of needle and position

Set correct clearance

between needle and hook

and check if the hook is

not

damaged

www.garudan.cz

Summary of Contents for GPS/X-3525 Series

Page 5: ...ANITA MP03200EN_180810 5 2 DESCRIPTION Fig 1 w w w g a r u d a n c z...

Page 32: ......

Page 36: ...ANITA MP03200EN_180822 4 A FRAME AND MACHINE BODY PARTS w w w g a r u d a n c z...

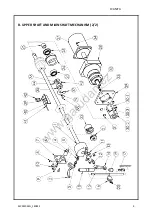

Page 38: ...ANITA MP03200EN_180822 6 B UPPER SHAFT AND MAIN SHAFT MECHANISM 1 2 w w w g a r u d a n c z...

Page 42: ...ANITA MP03200EN_180822 10 C PRESSER FOOT MECHANISM 1 2 w w w g a r u d a n c z...

Page 44: ...ANITA MP03200EN_180822 12 C PRESSER FOOT MECHANISM 2 2 w w w g a r u d a n c z...

Page 46: ...ANITA MP03200EN_180822 14 D LOWER SHAFT AND SHUTTLE MECHANISM 1 2 w w w g a r u d a n c z...

Page 48: ...ANITA MP03200EN_180822 16 D LOWER SHAFT AND SHUTTLE MECHANISM 2 2 w w w g a r u d a n c z...

Page 50: ...ANITA MP03200EN_180822 18 E THREAD TRIMMING MECHANISM 1 2 w w w g a r u d a n c z...

Page 54: ...ANITA MP03200EN_180822 22 G X MOVING MECHANISM 1 2 w w w g a r u d a n c z...

Page 56: ...ANITA MP03200EN_180822 24 G X MOVING MECHANISM 2 2 w w w g a r u d a n c z...

Page 58: ...ANITA MP03200EN_180822 26 I FEED FRAME MECHANISM 1 2 w w w g a r u d a n c z...

Page 60: ...ANITA MP03200EN_180822 28 I FEED FRAME MECHANISM 2 2 w w w g a r u d a n c z...

Page 62: ...ANITA MP03200EN_180822 30 I2 FEED FRAME FOR CUSTOMER DESIGN w w w g a r u d a n c z...

Page 64: ...ANITA MP03200EN_180822 32 J THREAD TENSION MECHANISM w w w g a r u d a n c z...

Page 66: ...ANITA MP03200EN_180822 34 K BOBBIN WINDER AND HAND PULLEY w w w g a r u d a n c z...

Page 68: ...ANITA MP03200EN_180822 36 L STAND AND TABLE w w w g a r u d a n c z...

Page 70: ...ANITA MP03200EN_180822 38 M LUBRICATION PARTS w w w g a r u d a n c z...

Page 72: ...ANITA MP03200EN_180822 40 N AIR CONTROL PARTS w w w g a r u d a n c z...

Page 74: ...ANITA MP03200EN_180822 42 Q OPERATION UNIT AND THREAD STAND w w w g a r u d a n c z...

Page 76: ...ANITA MP03200EN_180822 44 R CONTROL BOX w w w g a r u d a n c z...

Page 78: ...ANITA MP03200EN_180822 46 S OPTION w w w g a r u d a n c z...