10.1.

BASIC INSTRUCTIONS

In addition to following all operating procedures as directed by supervisors the operator

of a Magnascanner CS 5000 detector has only these responsibilities:

¥

Assure that the detector is always operating properly;

¥

Select

Off

and

Operate / On

modes;

¥

Regulate volume of the alarm;

¥

Read and/or reset the counter;

¥

Respond to all alarms.

10.2.

LCD REPORTS INFORMATION

The LCD on an overhead panel of the detector reports information concerning the unit s

calibration and operation. This includes program data, sensitivity settings, operator set-

tings and fault indication. A bright

LED bar graph

, easily visible from a distance, reports

detection levels and separate lights indicate ready and alarm conditions. All regulation

and control functions are self-prompting with necessary commands shown automati-

cally on the LCD. The unit also features the capability to report a traffic count on its

LCD.

Exact control of the unit s sensitivity is assured by a system with 200 precise and

repeatable steps for each program level, regulated by state-of-the-art touchpads and

reported visually on the LCD. Improved security of the unit s detection settings comes

from a totally new system of access codes. Two levels of codes eliminate the need for

bothersome keys for locked doors or other protective devices, while the Magnascan-

ner s circuitry provides precise accuracy of calibration never before achieved. Access

Code #1 is used by supervisors for selecting programs and sensitivity, with Access

Code #2 designed for initial set-up and overall control. All settings are encoded by

touchpads and stored in a resettable memory.

Security of the unit s calibration settings is further protected by a non-resettable

sequence code that allows supervisors to keep a log of all changes that are ever made

to the program, sensitivity or set up, as well as any unsuccessful attempt at changing

them. In addition, a tamper indication reports any unauthorized attempts at access.

A complete and automatic self-diagnostic program is carried out by the Magnascanner

CS 5000 each time the

OPERATE

touchpad is pressed. In addition, the detector uti-

lizes self-testing circuitry that enables it to identify and report automatically the failure of

elements that would affect operation of the unit.

10.3.

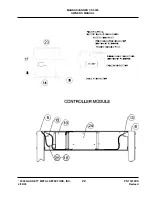

CONTROLS LCD DISPLAY

Large alpha/numeric display on the Control Panel, backlit for easy viewing, reports (in

words) all regulating, controlling and self-prompting functions of the unit. Because the

unit is designed to be user-friendly, all regulation and control functions are self-

prompting with necessary commands shown on the LCD display. Operators should fol-

low instructions of supervisors concerning responses to these commands.

26

MAGNASCANNER CS 5000

OWNER S MANUAL

2000 GARRETT METAL DETECTORS, INC.

4/30/00

PN 11674XX

Revised