13–10–612 Page 37

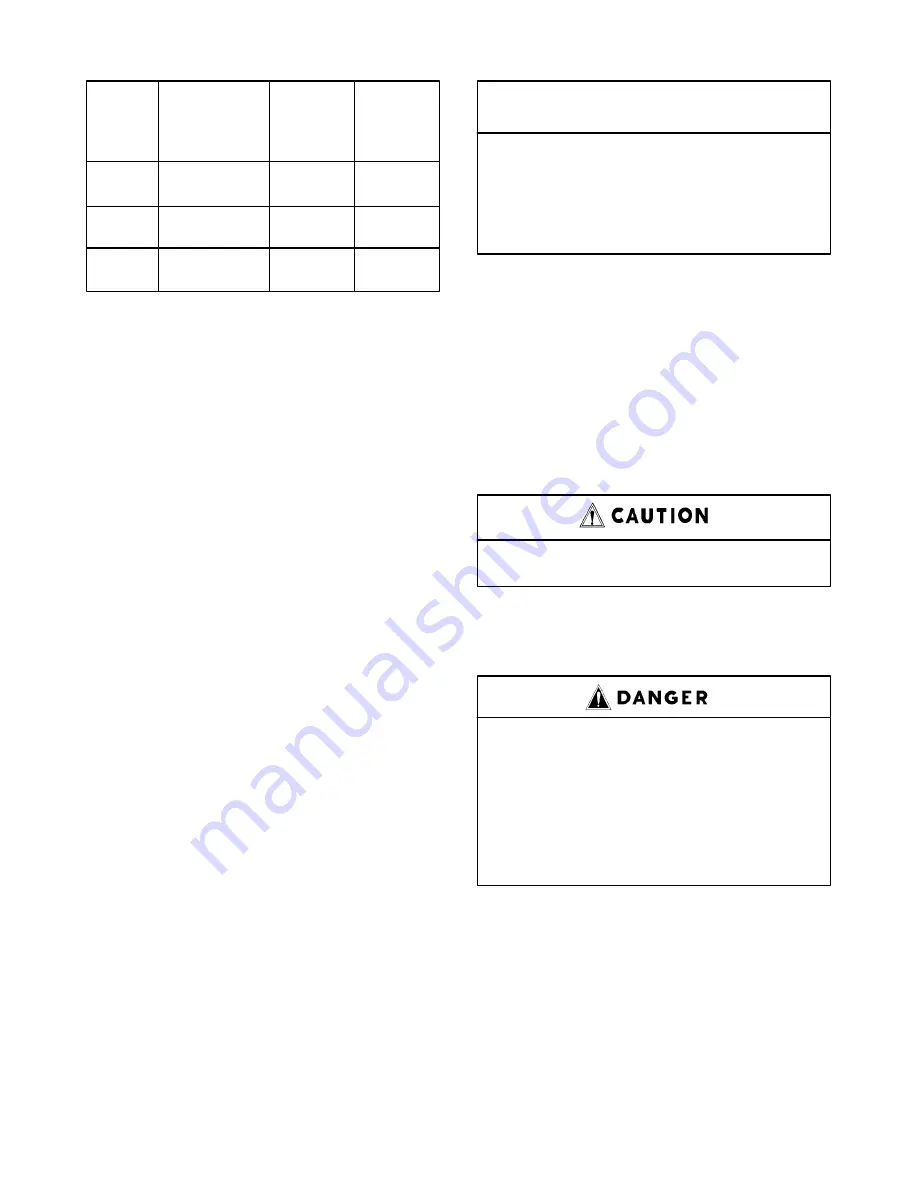

Approx.

Oil

Qty. – Top

System

Reservoir

of ADD to

Capacity

Capacity**

Centerline

Size

(Initial Fill)

(Refill)

of RUN

200 HP

Air Cld* – 57

50

11

Water Cld – 53

250 HP

Air Cld* – 57

50

11

Water Cld – 53

300 HP

Air Cld* – 80

70

12

Water Cld – 75

*

System capacity shown is for the initial fill of the compressor

unit and oil cooler module ONLY – remotely mounted oil cool-

ers will require additional oil to fill the piping between the com-

pressor unit and the oil cooler.

**

The oil reservoir refill quantity shown is measured at the cent-

erline of the oil level gauge RUN range or approximately 3.5

inches below the centerline of the oil reservoir.

FIGURE 5–2 – OIL SYSTEM CAPACITIES

(APPROXIMATE) – U.S. GALLONS

OIL LEVEL GAUGE (FIGURE 1–3, page 2) indicate

the amount of oil in the oil reservoir. When the unit is

stopped, the oil level will be higher in the RUN range

than when operating on load. When the unit is operat-

ing, the oil level should be near the center of the RUN

range. In normal operation, the oil level will fluctuate

slightly as the compressor loads and unloads. Add oil

only when the oil level gauge indicates in the ADD OIL

range when the compressor is loaded. Drain oil only

when the oil level gauge indicates EXCESS OIL when

the compressor is loaded.

MOISTURE IN THE OIL SYSTEM – In normal humid-

ity and with normal operating temperatures and pres-

sures, the thermal mixing valve controls the oil temper-

ature and prevents moisture contamination of the oil.

Unusual cooling of the oil reservoir, short loaded cycle

in high humidity, malfunctions of the thermal valve or

cooling water system may result in moisture in the oil

system which is detrimental to compressor lubrication

and could cause oil carryover. If moisture is observed

in the oil reservoir, drain the moisture and correct the

condition causing the accumulation. See ”Compressor

Oil System Check” and ”Thermal Control (Thermostat-

ic Mixing) Valve” in this section.

OIL CHANGE INTERVAL – Recommended oil change

intervals are based on oil temperature. FIGURE 5–3

shows how the Auto Sentry ES Controller figures the

oil change interval at various temperatures.

Discharge

AEON 4000

AEON 9000 SP

Temperature

Change Interval

Change Interval

Up to 180

_

F

6000 hrs.

8000 hrs.

180 to 190

_

F

4500 hrs.

6000 hrs.

190 to 200

_

F

3000 hrs.

4000 hrs.

200 +

1500 hrs.

2000 hrs.

FIGURE 5–3 – OIL CHANGE INTERVAL

When operating conditions are severe (very dusty, high

humidity, etc.) it will be necessary to change the oil

more frequently. Operating conditions and the appear-

ance of the drained oil must be surveyed and the oil

change intervals planned accordingly by the user.

Gardner Denver offers a free oil analysis program with

the AEON lubricants and we recommend a sample be

sent in at 1000 hours on a new unit.

Change the oil filter every 1000 hours.

DRAINING AND CLEANING OIL SYSTEM –

Air/oil under pressure will cause

severe personal injury or death. Shut

down compressor, relieve system of

all pressure, disconnect, tag and

lockout power supply to the starter

before removing valves, caps, plugs,

fittings, bolts, and filters.

Always drain the complete system. Draining when the

oil is hot will help to prevent varnish deposits and carry

away impurities. To drain the system, use one of the

following methods:

1.

If the unit is not elevated high enough to use the

oil reservoir drain line to drain oil, a small hand,

electric or air operated pump should be used to

drain reservoir through the oil filler opening or from

the drain valve. Remove the oil cooler drain plug.

Summary of Contents for ELECTRA-SAVER EAU PD - 200 HP

Page 13: ...13 10 612 Page 3 FIGURE 1 4 STARTER BOX FIGURE 1 5 PACKAGE CONTROLLER AND STARTERS...

Page 16: ...13 10 612 Page 6 DECALS 206EAQ077 212EAQ077 218EAQ077 211EAQ077 207EAQ077...

Page 17: ...13 10 612 Page 7 DECALS 216EAQ077 217EAQ077 222EAQ077 221EAQ077 208EAQ077...

Page 40: ...13 10 612 Page 30 FIGURE 4 8 CONTROL SCHEMATIC COMPRESSOR AT FULL LOAD 214ECM797 Ref Drawing...

Page 42: ...13 10 612 Page 32 FIGURE 4 10 WIRING DIAGRAM 212EAP546 Ref Drawing...

Page 43: ...13 10 612 Page 33 FIGURE 4 11 AUTO SENTRY ES CONTROLLER DISPLAY...

Page 45: ...13 10 612 Page 35 FIGURE 5 1 FLOW DIAGRAM AIR OIL SYSTEM 215EAU797 Ref Drawing...

Page 65: ......