32

SERVICING 6

SERVICING 6

SERVICING 6

SERVICING 6

SERVICING 6

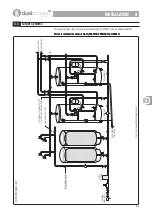

The Dualstream system should have a routine service at least once in 12 months.

IMPORTANT Always turn off the heating system and electricity supply to

the Dualstream before working on the Dualstream System.

6-1.1 Service Procedure

1.

Confirm with customer service history and locate Benchmark Logbook.

2.

Check cylinder model and serial number is listed in the Benchmark Logbook.

3.

Visually inspect cylinder/s for damage, metal failure and signs of leaks.

4.

Visually inspect accumulator for damage, metal failure and signs of leaks.

5.

When applicable visually inspect expansion vessel and its pipework for damage,

metal failure and signs of leaks.

6.

Visually inspect all Dualstream pipework for damage, metal failure and signs of

leaks.

7.

Record mains pressure and system pressure.

8.

Turn the Heating System OFF.

9.

Turn the electrical supply to the Dualstream OFF.

10. Momentarily open the combination TPR Valve and check that the water drains freely

and safely to and from the tundish.

11. Open cylinder TPRV for 15 seconds and close, valve should shut off. Repeat if valve

sticks. If valve will not shut off replace valve.

12. Open combination PRV for 15 seconds and close, valve should shut off. Repeat if

valve sticks. If valve will not shut off replace valve.

13. Close the Stop Cock.

14. Open the hot and cold taps, attach a hose to the cylinder and accumulator drain

cocks and empty the system.

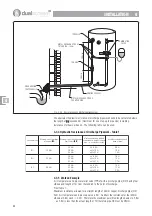

15. Check the pressure of the accumulator, this should be 1.5 Bar below the mains

pressure with an absolute minimum of 0.5/0.8 Bar.

16. Remove Immersion Heater, remove limescale and examine the element.

In hard water areas it is probably better to replace the Immersion Heater if heavily

scaled. Refit Immersion Heater with gasket.

17. Most glass lined cylinders will have at least one magnesium anode, remove and

inspect all anodes, replace if required.

18. Clean and check the line strainer in the combination valve - replace if required.

19. Check and clean the expansion relief valve in the combination valve - replace if

required.

20. Close all drain cocks and refill system.

21. Check that no water is passing through the Combination Valve or the Pressure Relief

Valves, this will be evident at the Tundish.

22. Switch on the heating system.

23. Check operation of motorised valve by setting heating system to call for hot water.

The valve should open. Then turn hot water off - the valve should close.

24. Wait for the system to heat up.

25. Check temperature of tap water adjust as required, max. 60°C.

26. Check operation of cylinder thermostat. When turned down below tank temperature

the motorised valve should open. When turned up above tank temperature the

motorised valve should close.

27. Check for leaks again when the system is up to temperature.

28. Enter details of service into the Benchmark Logbook.

6-1

Routine Service

Note

If heavy scaling is evident then descaling

the system is recommended. Ensure

system is fully flushed following descaling.

IMPORTANT

Also carry out any service

requirements of specific

components as specified by the

manufacturers instructions.

66666