2

Important Health and Safety Information for Installers and Service Engineers

Health and Safety at Work Act 1974

Consumer Protection Act 1987

COSHH Regulations 1988

The following information is given as a requirement of the

above legislation.

Great care is taken by GAH (HEATING PRODUCTS) LIMITED to

ensure that Dualstream systems are designed and

manufactured to meet general safety requirements when

properly used and installed as recommended in this manual.

It is the responsibility of Users and Engineers to ensure that

adequate protective clothing and glasses are worn when

working with the Dualstream system.

SEALS AND INSULATION

SEALS AND INSULATION

SEALS AND INSULATION

SEALS AND INSULATION

SEALS AND INSULATION

Insulation and sealing materials are used in the construction of

the Dualstream cylinders. Units are sealed and when used in

the manner for which they are intended the insulating and

sealing materials do not present any known hazard. However

always observe the following recommendations:-

1.

Avoid inhalation of fibres or dust, wear face mask.

2.

Avoid eye contamination by fibres or dust - wear eye

protection.

3.

As far as possible avoid any skin contact with Fibreglass

Insulation, Glass Rope, Mineral Wool, Insulation Pads and

Ceramic Fibre.

GAH (HEATING PRODUCTS) LIMITED will not accept

responsibility for any damage or personal injury caused

by not giving due consideration to the above safety

recommendations.

OTHER MATERIALS

OTHER MATERIALS

OTHER MATERIALS

OTHER MATERIALS

OTHER MATERIALS

SEALANTS, ADHESIVES AND PAINTS

Sealants, Adhesives and Paints are used in the construction of

the Dualstream components. When used in the manner for

which they are intended they do not present any known hazard.

ELECTRIC

ELECTRIC

ELECTRIC

ELECTRIC

ELECTRIC

All cylinders have electrical supply of 240V (enough to

endanger life) connected to the Immersion Heater.

Always isolate before adjustment, servicing and repair.

All electrical installation and maintenance of the Dualstream

must be carried out by a competent qualified installer.

All electrical work must be installed to the requirements of

these ‘User and Installation Instructions’.

PPPPPatents GB 2349908

atents GB 2349908

atents GB 2349908

atents GB 2349908

atents GB 2349908

©

©

©

©

©

2012 GAH (HEATING PRODUCTS) L

2012 GAH (HEATING PRODUCTS) L

2012 GAH (HEATING PRODUCTS) L

2012 GAH (HEATING PRODUCTS) L

2012 GAH (HEATING PRODUCTS) LTD.

TD.

TD.

TD.

TD.

Dualstr

Dualstr

Dualstr

Dualstr

Dualstream is a T

eam is a T

eam is a T

eam is a T

eam is a Trademark of GAH (HEATING PRODUCTS) L

rademark of GAH (HEATING PRODUCTS) L

rademark of GAH (HEATING PRODUCTS) L

rademark of GAH (HEATING PRODUCTS) L

rademark of GAH (HEATING PRODUCTS) LTD.

TD.

TD.

TD.

TD.

Manual by Harber Technical Services Tel/Fax 01263 515444

E-mail:[email protected] www.harbertech.co.uk

GAH (Heating Pr

GAH (Heating Pr

GAH (Heating Pr

GAH (Heating Pr

GAH (Heating Products) Ltd.

oducts) Ltd.

oducts) Ltd.

oducts) Ltd.

oducts) Ltd.

Building 846

Bentwaters Parks

Rendlesham

Woodbridge

Suffolk IP12 2TW

TTTTTel:

el:

el:

el:

el: 01394 421160

01394 421160

01394 421160

01394 421160

01394 421160

Fax:

Fax:

Fax:

Fax:

Fax: 01394 421170

01394 421170

01394 421170

01394 421170

01394 421170

email: [email protected]

www.gah.co.uk

In pursuance of a policy of constant development, GAH (HEATING PRODUCTS) LIMITED

reserve the right to change any boiler part or design without notice, therefore certain

details included in this manual may not be correct at the time of printing. Any

modification and improvements detailed in this manual does not commit GAH to update

any system previously supplied.

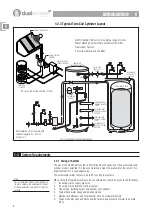

Front cover shows typical components.

Manual Part No. ...................015-15011

Manual Ref ..........................CS10

Issue ...................................7a

Date ....................................25/02/2013

HTS REF GAH Dualstream 250213 (Aquabravo cylinders)