iii

IMPORTANT NOTE TO USERS

READ CAREFULLY ALL OF THIS MANUAL BEFORE USING THIS PRODUCT.

IF NOT USED CORRECTLY, UNEXPECTED DAMAGES MAY BE CAUSED TO

THE USERS OR THE BYSTANDERS.

While all efforts have been made to ensure the accuracy of all information in this

manual, FUJITSU assumes no liability to any party for any damage caused by

errors or omissions or by statements of any kind in this manual, its updates or

supplements, whether such errors are omissions or statements resulting from

negligence, accidents, or any other cause. FUJITSU further assumes no liability

arising from the application or use of any product or system described herein; nor

any liability for incidental or consequential damages arising from the use of this

manual. FUJITSU disclaims all warranties regarding the information contained

herein, whether expressed, implied, or statutory.

FUJITSU reserves the right to make changes to any products herein, to improve

reliability, function, or design, without further notice and without obligation.

Summary of Contents for M3097DE

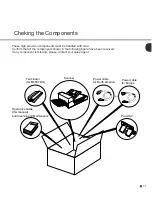

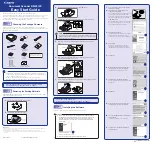

Page 1: ...C150 E100 01EN M3097DE DG Image Scanner Operator s Guide ...

Page 2: ...M3097DE DG Image Scanner Operator s Guide ...

Page 8: ...vi ...

Page 10: ...viii ...

Page 43: ...4 4 ...

Page 46: ...5 2 497 234 335 285 696 Dimensions unit mm ...

Page 59: ...6 10 ...

Page 69: ...IN 4 ...

Page 70: ......