Operation 8

Safety is a primary concern in the design and

manufacture of our products. Unfortunately, our

efforts to provide safe equipment can be wiped

out by an operator’s single careless act.

In addition to the design and configuration of

equipment, hazard control and accident preven-

tion are dependent upon the awareness, con-

cern, judgement, and proper training of person-

nel involved in the operation, transport, mainte-

nance and storage of equipment.

It has been said “The best safety device is an

informed, careful operator.”We ask you to be

that kind of operator.

The operator is responsible for the safe operation

of this equipment. The operator must be properly

trained. Operators should be familiar with the

equipment, the tractor, and all safety practices

before starting operation. Read the safety rules

and safety decals on pages 2-6.

Owner should check and tighten all hardware after

the first hour of operation. The break in stage of

your new disc harrow can cause minimal loosening

of disc gangs and other hardware as the new paint

wears. Please see Bolt Torque Chart (page 19) for

proper torque information.

• Power unit must be equipped with ROPS or

ROPS cab and seat belt. Keep seat belt

securely fastened. Falling off power unit can

result in death from being run over or crushed.

Keep foldable ROPS systems in “locked up”

position at all times.

• Never allow children or untrained persons to

operate equipment.

• Keep bystanders away from equipment.

• NEVER GO UNDERNEATH EQUIPMENT.

Never place any part of the body underneath

equipment or between moveable parts even

when the engine has been turned off. Hydraulic

Operation

WARNING

system leak down, hydraulic system failures,

mechanical failures, or movement of control

levers can cause equipment to drop or rotate

unexpectedly and cause severe injury or death.

• Service work does not require going under

-

neath.

• Read Manual for service instructions or have

service performed by a qualified dealer.

• Stop tractor and implement immediately upon

striking an obstruction. Turn off engine, remove

key, inspect, and repair any damage before

resuming operation.

•

Always wear relatively tight and belted clothing

to avoid entanglement in moving parts. Wear

sturdy, rough-soled work shoes and protective

equipment for eyes, hair, hands, hearing, and

head.

Owner/Operator

Pre-Operation

Checklist

(Owner’s/Operator’s Responsibility)

____ Review and follow all safety rules and

safety decal instructions on page 2 through

page 6.

____ Check that equipment is properly and

securely attached to tractor.

____ Check that all safety decals are installed

and in good condition. Replace if damaged.

____ Check that all hardware is properly

installed and secured.

____ Do not allow riders.

____ Make sure tractor ROPS or ROPS CAB

and seat belt are in good condition. Keep seat

belt securely fastened during operation.

Summary of Contents for DH1376

Page 1: ...DH13_5TL15193_7 10 2014 DH1376 DH1380 DH1396 DISK HARROWS O P E R A T O R S M A N U A L...

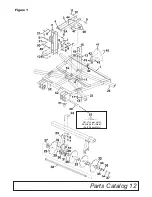

Page 15: ...Parts Catalog 12 Figure 1 Set of Lower Hitch Bushings for iMatch Sold Separately...

Page 23: ...Notes 20 Notes...

Page 24: ...2014 Monroe Tufline Manufacturing Inc All Rights Reserved PART NO 5TL15193...