6”x6” blocks securing

gang for storage

11 Owner Service

• NEVER GO UNDERNEATH EQUIPMENT.

Never place any part of the body underneath

equipment or between moveable parts even

when the engine has been turned off. Hydraulic

system leak down, hydraulic system failures,

mechanical failures, or movement of control

levers can cause equipment to drop or rotate

unexpectedly and cause severe injury or death.

• Service work does not require going under

-

neath.

• Read Manual for service instructions or have

service performed by a qualified dealer.

The information in this section is written for oper-

ators who possess basic mechanical skills. If you

need help, your dealer has trained service techni-

cians available. For your protection, read and

follow the safety information in this manual.

• Keep all persons away from operator control

area while performing adjustments, service, or

maintenance.

• Before dismounting power unit or performing

any service or maintenance, follow these steps:

disengage power to equipment, lower the 3 point

hitch and all raised components to the ground,

operate valve levers to release any hydraulic

pressure, set parking brake, stop engine, remove

key, and unfasten seat belt.

• Always wear relatively tight and belted clothing

to avoid entanglement in moving parts. Wear

sturdy, rough-soled work shoes and protective

equipment for eyes, hair, hands, hearing, and

head.

Gang Assembly for Maintenance

•

When performing maintenance or repairs make

sure the equipment is in the lowered position

and both the mainframe and gangs are properly

blocked and secured to prevent rolling. Failure

to do so can cause serious injury or death.

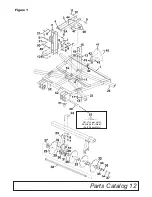

When gang component replacement is required,

carefully observe all safety issues. Place unit on

level ground prior to gang drop. Also make sure

that gangs are blocked to keep them from rolling

in either direction. After unit is lowered to ground

and gangs are secure, loosen nuts on all hex

bolts holding hangers to main frame (item 10).

Observe the sequence and location of each

gang component and refer to the gang diagram

on Figure 1 for removal and replacement of the

desired component. After replacement is com-

pleted reinstall gang parts in proper order as

shown on gang diagram on Figure 1. Make sure

that the gang nut on the gang axle is properly

tightened after replacements are made. Refer to

" Bolt Tightening Torque Chart" on page 19 for

proper torque.

Storage

When storing your disc harrow make sure the

unit is placed on level ground and that the gangs

are properly chocked by bracing with 6”x6”

blocks on the front and rear side of one com-

plete gang assembly. See the diagram below.

WARNING

WARNING

WARNING

CAUTION

Owner Service

Summary of Contents for DH1376

Page 1: ...DH13_5TL15193_7 10 2014 DH1376 DH1380 DH1396 DISK HARROWS O P E R A T O R S M A N U A L...

Page 15: ...Parts Catalog 12 Figure 1 Set of Lower Hitch Bushings for iMatch Sold Separately...

Page 23: ...Notes 20 Notes...

Page 24: ...2014 Monroe Tufline Manufacturing Inc All Rights Reserved PART NO 5TL15193...