Adjusting Gang Angles

When making gang adjustments, be careful to

keep hands and feet clear of sliding parts and

possible pinch points.

The gang angles on the DH13 series disc are

adjustable. The unit should be lifted two to

three inches off the ground with the tractor

hitch system for an easier adjustment. Remove

cotter key and then pin and set angle at the desired

setting. Make sure that the pin and cotter key is

replaced properly after setting to secure the gang

angles. (See photos below)

It is important that only one adjustment be

made at a time and then tried between each

9 Operation

adjustment. Remember each adjustment affects

another; therefore, extreme care should be

used when adjusting.

Each trial run should be made with the tractor in

the same gear and approximately the same

RPM. Changing discing speed while attempting

to adjust will result in excessive time and labor

loss due to changing conditions.

While making your initial run, observe the disc

closely as it is traveling. It should be level from

the front to rear as it travels. If not, level it by

adjustment of your tractor top link. After making

the necessary adjustment, the disc should pull

level with both front and rear gangs penetrating

the soil at approximately the same depth.

Now observe the soil behind the disc. It should

be level and smooth. If after making the above

adjustments, the disc leaves a water furrow in

the center, it would indicate that the front gangs

are more aggressive than the rear gangs. To

correct this, either increase the angle of the rear

gangs or decrease the angle of the front gangs.

Conversely, if the disc is ridging, that is leaving

a ridge behind it, this would indicate that the

rear gang is more aggressive than the front

gang. To correct this, either decrease the angle

of the rear gang or increase the angle of the

front gangs.

CAUTION

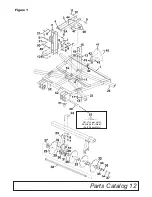

Summary of Contents for DH1376

Page 1: ...DH13_5TL15193_7 10 2014 DH1376 DH1380 DH1396 DISK HARROWS O P E R A T O R S M A N U A L...

Page 15: ...Parts Catalog 12 Figure 1 Set of Lower Hitch Bushings for iMatch Sold Separately...

Page 23: ...Notes 20 Notes...

Page 24: ...2014 Monroe Tufline Manufacturing Inc All Rights Reserved PART NO 5TL15193...