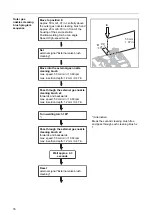

Cleaning brushes do not run

Compressed air supply interrupted

Set up the compressed air supply

Compressed air supply line faulty or dirty

Clean compressed air supply line and replace if necessary

Brush motor faulty

Inform service team

Valve faulty

Inform service team

No signal at the valve

Check programming;

Check connections to the robot control unit

Cause:

Remedy:

Cause:

Remedy:

Cause:

Remedy:

Cause:

Remedy:

Cause:

Remedy:

High-pressure gas purging not working

Compressed air supply interrupted

Set up the compressed air supply

Compressed air supply line faulty or dirty

Clean compressed air supply line and replace if necessary

Pressure regulator not set correctly

Check pressure at pressure regulator, set pressure to 5.5 - 6 bar

Pressure booster faulty

Contact After-Sales Service

Inlet pressure at the pressure booster too low

Check inlet pressure

Valve faulty

Contact After-Sales Service

Nozzle blocked

Clean nozzle, replace if necessary

Cause:

Remedy:

Cause:

Remedy:

Cause:

Remedy:

Cause:

Remedy:

Cause:

Remedy:

Cause:

Remedy:

Cause:

Remedy:

Pores in the weld seam

Too much parting agent in the inside of the welding torch

Remove residues of parting agent by blowing out the inside of the welding

torch. Ensure supply of compressed air

Too much parting agent in the inside of the welding torch

Reduce parting agent injection quantity (shorten duty cycle of pump for part-

ing agent)

Cause:

Remedy:

Cause:

Remedy:

90

Summary of Contents for Robacta TSS /i

Page 2: ......

Page 11: ...General 11 ...

Page 12: ...12 ...

Page 18: ...18 ...

Page 19: ...Operating controls connections and mechanical components 19 ...

Page 20: ...20 ...

Page 32: ...32 ...

Page 33: ...Installation and Startup 33 ...

Page 34: ...34 ...

Page 61: ...12 12 12 Connect the compressed air supply 61 EN US ...

Page 64: ...64 ...

Page 65: ...Cleaning Program Sequence 65 ...

Page 66: ...66 ...

Page 68: ...A B C D E F G 68 ...

Page 79: ...Reset external signal Internal valve brush cleaning 79 EN US ...

Page 84: ...Reset external signal Cut wire electrode End of the cleaning process Welding 84 ...

Page 85: ...Troubleshooting Maintenance and Disposal 85 ...

Page 86: ...86 ...

Page 97: ...Appendix 97 ...

Page 98: ...98 ...