General information

Wire cutter

The wire cutter can be used to cut two wire electrodes with a diameter of up to 1.6 mm

(0.063 in.)

The opening and closing of the wire cutter is triggered by an active signal from the robot

controls.

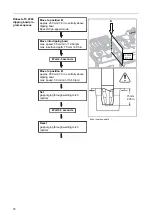

TC 2000 dipping

bowl

The use of the dipping bowl is recommended in the case of:

-

gas-cooled welding torches

-

water-cooled welding torches in the higher power range (hot gas nozzles)

Advantages:

-

The spatter accumulation on the gas nozzle loosens.

-

The welding torch is also cooled.

-

The anti-stick agent contained in the parting agent prevents new contaminations.

max. 75 mm

(2.95 in.)

(1)

NOTE!

Immerse welding torch a maximum of

75 mm (2.95 in.) into the dipping bowl.

▶

The gas holes (1) must remain dry.

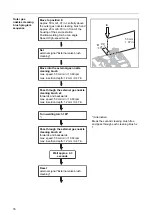

Robacta TC 2000

Robacta TC 2000 is an electromagnetic cleaning unit for welding torch cleaning in steel

applications.

After 50 seconds of charging time, the maximum magnetic flux density is available for

the cleaning process.

The cleaning process (discharge process) is initiated by the “Cleaning start” signal.

Specification of

the Parting Agent

Volume

In the case of high-pressure gas purging with parting agent, the parting agent volume is

specified via the duration of the external “Pump for parting agent” signal.

The longer the signal is present, the more parting agent is injected.

Cleaning End

without Touch

Sense Option

If the Touch Sense option is not installed on the service station, then the cleaning pro-

cess is ended at the wire cutter.

69

EN-US

Summary of Contents for Robacta TSS /i

Page 2: ......

Page 11: ...General 11 ...

Page 12: ...12 ...

Page 18: ...18 ...

Page 19: ...Operating controls connections and mechanical components 19 ...

Page 20: ...20 ...

Page 32: ...32 ...

Page 33: ...Installation and Startup 33 ...

Page 34: ...34 ...

Page 61: ...12 12 12 Connect the compressed air supply 61 EN US ...

Page 64: ...64 ...

Page 65: ...Cleaning Program Sequence 65 ...

Page 66: ...66 ...

Page 68: ...A B C D E F G 68 ...

Page 79: ...Reset external signal Internal valve brush cleaning 79 EN US ...

Page 84: ...Reset external signal Cut wire electrode End of the cleaning process Welding 84 ...

Page 85: ...Troubleshooting Maintenance and Disposal 85 ...

Page 86: ...86 ...

Page 97: ...Appendix 97 ...

Page 98: ...98 ...