USER INSTRUCTIONS POLYCHEM GRP ENGLISH 71569132 12-04A

Page 43 of 52

flowserve.com

The elastomer O-ring located on the OD of the seal

has been sized to overfill the groove in which it is

located. When installing the seal into its

corresponding housing, in addition to compressing

the O-ring a certain amount of material may shear off.

This sheared material should be removed. An arbor

press should be used to install the seal.

Install the inboard seal in the bore of the bearing

housing (Group 1) or adapter (Group 2 and Group 3)

with the single expulsion port positioned at the 6

o’clock position.

Install the outboard seal in the bore of the bearing

carrier. There are no orientation issues since this is a

multiport design seal.

6.10.1.2c Magnetic seals

Follow the installation instructions provided by the

manufacturer.

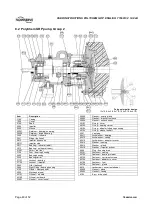

6.10.1.3 Bearing carrier/power end assembly

a) Install new O-rings [4610.2] onto the bearing

carrier. Slide the bearing carrier [3240] over the

outboard bearing [3013].

b) Install the outboard bearing retaining device.

Double row bearings on Group 1 and 2 pumps

.

Slide the snap ring [2530.1] in place with its flat

side against the outboard bearing and snap it into

its groove in the bearing carrier.

Duplex angular contact bearings on Group 1 and

2 pumps and all bearings on Group 3 pumps

.

Slide the bearing retainer [2530.2] against the

outboard bearing and install and tighten the

socket head capscrews [6570.2]. (See figure 6-2

for correct torque values.)

Never compress the snap ring

unless it is positioned around the shaft and between

the bearings. In this configuration, it is contained

therefore if it should slip off the compression tool it

is unlikely to cause serious injury.

c) The shaft, bearings, and bearing carrier

assembly (figure 6-14) can now be installed into

the bearing housing [3200]. The bearing carrier

[3240] should be lubricated with oil on the O-rings

and threads before installing the assembly into

the bearing housing. Thread the bearing carrier

into the bearing housing by turning it clockwise to

engage the threads. Thread the carrier onto the

housing until the carrier flange is approximately

3mm (

1

/

8

in.) from the housing. Install the set

screws [6570.3] loosely.

d) Reinstall any tags, plugs, site gages and oiler.

Mark 3A design

. Install the following items onto

the bearing housing; oil level tag (figure 6-18)

and combination Trico oiler/site gage [3855],

vent/breather [6521] and drain plug [6569].

ANSI 3A design

. Install the following items onto

the bearing housing; oil level tag (figure 6-18)

and site gage [3855], plug [6521] and magnetic

drain plug [6559].

e) On Group 2 and 3 pumps, assemble the bearing

housing adapter [1340] to the bearing housing

[3200]. Be sure to install a new O-ring [4610.3].

Mark 3A and ANSI 3A design

. Thread the

capscrews [6570.6] through the adapter and into

the tapped holes in the bearing housing.

f) If the power end used lip seals, install the flinger

(deflector) [2540] onto the shaft [2100].

g) Slide the sleeve [2400] onto the shaft ensuring

that the flinger o-ring and flinger slip under the

end of the sleeve.

6.10.2 Seal and rear cover assembly

a) With an external seal slide the rotating part of the

seal over the sleeve but do not tighten the

setscrews at this time.

b) Position the seat to gland gasket [4590.2] and

seal seat into the gland [4120] and slide this

assembly over the sleeve.

c) With a cartridge seal, slide the seal over the sleeve,

but do not tighten the setscrews at this time.

d) For non-cartridge internal seals, install the stationary

seal face and its gasket or O-ring into the gland.

e) Place the cover nose gasket into the gland (or

the cover to gland gasket on Groups 3 and 4)

and slide them all over the sleeve.

f) With an internal seal, position the rotating portion

of the seal on the sleeve as shown on the seal

drawing provided, or as marked on the sleeve

during disassembly. It may be necessary to

assemble the pump to the impeller clearance

setting stage to properly locate the shaft (if the

rotor has been moved). Mark the end of the box

on the shaft and then disassemble the pump

back to this stage. This is because seal setting is

measured from the end of the box.

g) If they were removed, assemble the gland studs

[6572] into the cover [1220], replace the box

extension onto the cover and slide the gland over

the sleeve.

h) Assemble the cover onto the bearing housing

[3200] on Group 1 or support head [1340] using

bolts [6570.4] and lockwashers [6541.3] and

torque up to 20 Nm (15 lbf

•

ft). (For 2K3x1.5G-10,

2K4x3G-10 and 2K6x4G-10 units use eccentric

washers and nuts instead.)