USER INSTRUCTIONS POLYCHEM GRP ENGLISH 71569132 12-04A

Page 12 of 52

flowserve.com

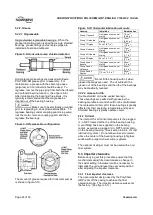

Figure 3-1

3.3 Design of major parts

3.3.1 Pump casing

The pump casing is designed with a horizontal

centerline suction inlet and a vertical centerline top

discharge which makes it self venting.

Removal of the casing is not required when

performing maintenance of the rotating element. The

pump is designed with a gasket perpendicular to the

shaft allowing the rotating element to be easily

removed (back pull out).

3.3.2 Impeller

An open impeller design is the only offering.

3.3.3 Shaft/sleeve

The pump shafts are sleeved, supported on rolling

element bearings, with both threaded and polygon

drive ends for the impeller and a keyed drive end.

3.3.4 Pump bearings and lubrication

Ball bearings are fitted as standard and may be either

oil or grease lubricated.

3.3.5 Bearing housing

Options include a large reservoir for oil bath

lubrication or the use of zerk fittings for regreasable

bearings. A micrometer shaft adjustment allows

external setting of the impeller gap.

3.3.6 Seal chamber (cover plate)

The seal chamber has a spigot (rabbet) fit between

the pump casing and bearing housing (adapter) for

optimum concentricity. The design enables a number

of sealing options to be fitted.

3.3.7 Shaft seal

The mechanical seal(s), attached to the pump shaft,

seals the pumped liquid from the environment. Gland

packing may be fitted as an option.

3.3.8 Driver

The driver is normally an electric motor. Different drive

configurations may be fitted such as internal combustion

engines, turbines, hydraulic motors etc driving via

couplings, belts, gearboxes, drive shafts etc.

3.3.9 Accessories

Accessories may be fitted when specified by the

customer.

3.4 Performance and operating limits

This product has been selected to meet the

specification of your purchase order. (See section 1.5.)

Typical materials used in the PolyChem GRP include:

Casing, impeller, rear cover, and glands.

Glass

reinforced plastic (GRP) composed of chopped

fiberglass strands in a Derakane 470™ vinyl ester

resin. (Durcon 730, a glass reinforced thermo-setting

epoxy resin, is used for the 1K3x2GS-7.)

Shaft sleeves

. Ryton

plastic (Polyphenylene

sulfide) or high alloy steels are available.

Shafting

. 4140 carbon steel as standard with 17-4

PH stainless steel as an option. (Superchlor 77 is the

standard shaft material for the 1K3x2GS-7 pump.)

3.4.1 Pressure-temperature ratings

Figure 3-2

Bar (psi)

Size

-46 °C

(-50 °F)

66 °C

(150 °F)

121 °C

(250 °F)

1J1.5x1G-6

13.79 (200)

13.79 (200)

10.34 (150)

1J3x1.5G-6

13.79 (200)

13.79 (200)

10.34 (150)

1J3x2G-6

13.79 (200)

13.79 (200)

10.34 (150)

1J1.5x1G-8

13.79 (200)

13.79 (200)

10.34 (150)

2K3x1.5G-8

13.79 (200)

13.79 (200)

10.34 (150)

2K3x2G-8

13.79 (200)

13.79 (200)

10.34 (150)

2K4x3G-8

13.79 (200)

13.79 (200)

10.34 (150)

2K2x1G-10

17.24 (250)

17.24 (250)

13.79 (200)

2K3x1.5G-10

6.89 (100)

6.89 (100)

5.17 (75)

2K4x3G-10

6.89 (100)

6.89 (100)

5.17 (75)

2K6x4G-10

6.89 (100)

6.89 (100)

5.17 (75)

2K3x1.5G-13

8.62 (125)

8.62 (125)

6.89 (100)

2K4x3G-13

8.62 (125)

8.62 (125)

6.89 (100)

3J8x6G-13

10.34 (150)

10.34 (150)

8.62 (125)

3J12x10G-15

6.89 (100)

6.89 (100)

5.17 (75)

4J12x10G-15B

6.89 (100)

6.89 (100)

5.17 (75)

Size

-29 °C

(-20 °F)

66 °C

(150 °F)

107 °C

(225 °F)

1K3x2GS-7

9.31 (135)

9.31 (135)

9.31 (135)

2K4X3G-13/12.5

Serial No.

Equipment No.

Purchase Order

Model

Size

MDP

Material

Date DD/MMM/YY