USER INSTRUCTIONS POLYCHEM GRP ENGLISH 71569132 12-04A

Page 27 of 52

flowserve.com

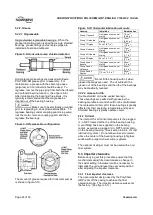

Figure 5-11: Final impeller clearance setting

Pump frame size

Impeller gap to casing

Group 1 and 2

0.38 mm (0.015 in.)

3J 8x6G-14

0.51 mm (0.020 in.)

3J 12x10G-15 and 4J 12x10G-15B

0.63 mm (0.025 in.)

The rotation of bearing carrier from center of one lug

on the bearing carrier to center of next lug results in

axial shaft movement of 0.1 mm (0.004 in.).

5.3.2 Initial impeller setting

Initial impeller clearance is set off the rear cover since

the casing is typically left in the piping during servicing

of the power end and seal. The initial setting is meant

to get the impeller close to the casing so that final

adjustment does not upset the mechanical seal

setting. The tabulated dimension “X” (see fig. 5

-12

and 5-13) can be preset during assembly of the power

end prior to installation into the casing.

Figure 5-12: Initial impeller setting

Figure 5-

13: Initial impeller back setting “X”

Pump size

Setting distance

1J1k1½ x 1 x 6

3.22 mm (0.127 in.)

1J3 x 1½ x 6

0.91 mm (0.036 in.)

1J3 x 2 x 6K

13.16 mm (0.518 in.)

1J1½ x 1 x 8

0.91 mm (0.036 in.)

2K3 x 1½ x 8

4.16 mm (0.164 in.)

2K3 x 2 x 8

3.17 mm (0.125 in.)

2K4 x 3 x 8

5.51 mm (0.217 in.)

2K2 x 1 x 10

2.36 mm (0.093 in.)

2K3 x 1½ x 10

15.54 mm (0.612 in.)

2K4 x 3 x 10

15.54 mm (0.612 in.)

2K6 x 4 x 10

11.70 mm (0.461 in.)

2K3 x 1½ x 13

0.79 mm (0.031 in.)

2K4 x 3 x 13

0.79 mm (0.031 in.)

3J8 x 6 x 13

1.57 mm (0.062 in.)

3J12 x 10 x 15

17.45 mm (0.687 in)

4J12 x 10 x 15B

17.45 mm (0.687 in)

5.4 Direction of rotation

5.4.1 Rotation check

It is absolutely essential that the

rotation of the motor is checked before connecting

the shaft coupling. Incorrect rotation of the pump, for

even a short time, can dislodge and damage the

impeller, casing, shaft and shaft seal. All PolyChem

GRP pumps turn clockwise as viewed from the motor

end. Make sure the motor rotates in the same

direction.

If maintenance work has been carried

out to the site's electricity supply, the direction of

rotation should be re-checked as above in case the

supply phasing has been altered.

5.4.2 Coupling installation

The coupling (figure 5-14) should be

installed as advised by the coupling manufacturer.

Pumps are shipped without the spacer installed. If

the spacer has been installed to facilitate alignment,

then it must be removed prior to checking rotation.

Remove all protective material from the coupling and

shaft before installing the coupling.

Figure 5-14

5.5 Guarding

Power must never be applied to the

driver when the coupling guard is not installed.

5.5.1 Clam shell guard - standard

The standard coupling guard for all PolyChem pumps is

the “clam shell” design and is shown in figure 5

-15. It is

hinged at the top and can be removed by loosening one

of the foot bolts and sliding the support leg out from

under the cap screw. (Note that the foot is slotted).

The leg can then be rotated upward and half of the

guard can be disengaged (unhinged) from the other.

(Note that only one side of the guard needs to be

removed.) To reassemble simply reverse the above

procedure.