10

Onboard Weighing |

FT-30M

| www.flintec.com

Accuracy and Performance

Accuracy and Performance

This manual is primarily concerned with the installation and use of the Flintec FT-30M on board weighing indicator. Accuracy and

performance is dependent on the quality, type and installation quality of the load supporting load cells or sensors. The Flintec DSB7

range of vehicle weighing load cells are ideally suited. Please refer to the appropriate load cell installation manual for the load cells

installed. Optimum on-board weighing performance is obtained when the load cells are installed between the load-carrying body

(compactor body, tipper body, box, tank, flat-bed, etc.) and the vehicle chassis and carrying the entire weight of the superstructure

and payload. No weight-supporting structure other than the load cells, such as braces or gussets should attach the superstructure to

the chassis; this will result in an alternate load-path that will degrade weighing system accuracy. Typical applications include: waste

trucks, tippers, tankers, flat-beds and van type structures mounted on either truck chassis or trailer frame.

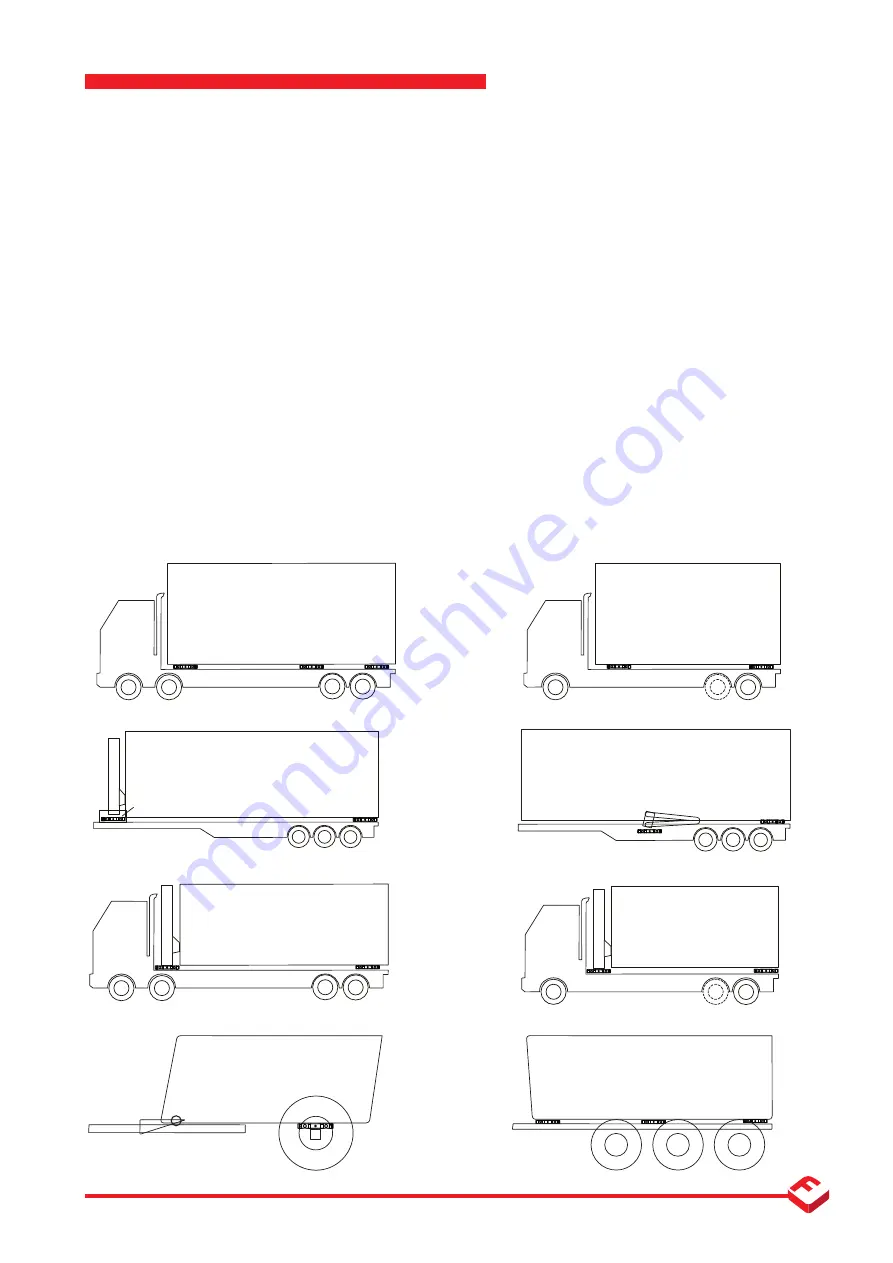

Truck bodies and payloads are supported above the chassis with load cells mounted directly to the truck frame (see example

illustrations below). This is usually accomplished by separating the suspension subframe from the body frame and installing load

cells between these structures. Air and fluid pressure sensors, extensometers and other forms of secondary sensor are routinely fitted

to vehicles. The FT-30M is compatible with any sensor with an output range up to 3.5 mV/V.

Applications

Installations are typically accomplished by separating the body frame from the chassis or trailer frame and installing load cells

between these typical vehicle structures;

MSB

Revision 19 April 2016

Accuracy and Performance

This manual is primarily concerned with the installation

and use of the Flintec FT-30M on board weighing

indicator. Accuracy and performance is dependant

on the quality, type and installation quality of the load

supporting load cells or sensors. The Flintec DSB7 range

of vehicle weighing load cells are ideally suited. Please

refer to the appropriate load cell installation manual

for the load cells installed. Optimum onboard weighing

performance is obtained when the load cells are installed

between the load-carrying body (compactor body, tipper

and carrying the entire weight of the superstructure

and payload. No weight-supporting structure other

than the load cells, such as braces or gussets should

attach the superstructure to the chassis; this will result

in an alternate load-path that will degrade weighing

system accuracy. Typical applications include: waste

mounted on either truck chassis or trailers. frame and

installing load cells between these structures

.

load cells between these typical vehicle structures;

Tipping Trailer

Under-body tipping arrangement

Tipping Trailer

Front end tipping arrangement

Load cell

Load cell

Load cell

Load cell

Load cell

Load cell

Load cell

Chassis

4 Axle Rigid Tipping Body

Load cell

Load cell

Chassis

2/3 Axle Rigid Fixed Body

2/3 Axle Rigid Tipping Body

Waste/Garbage truck, boxed truck

Waste/Garbage truck, boxed truck

Load cell

Chassis

Load cell

Load cell

Chassis

Load cell

Load cell

Load cell

Load cell

Agricultural

M

achines

Accuracy & performance

Truck bodies and payloads are supported above the

chassis with load cells mounted directly to the truck

frame (see example illustrations below) are usually

accomplished by separating the suspension subframe

from the trailer frame and installing load cells between

these structures

.

extensometers and (another secondry sensor).

Applications

Installations are typically accomplished by separating the

body frame from the chassis or trailer frame and installing

load cells between these typical vehicle structures;

Load cell

Agricultural

M

achines

Load pin

10

v1_000012_FT-30M 21/06/2016