DFLEX Assembly instructions |

47

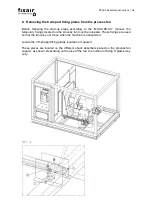

It must be applied between the joints of the modules, attempting to penetrate 3 to 5 mm

between the adjacent faces of the profiles.

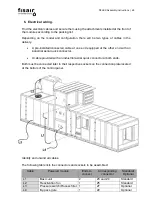

Once the sealant has been applied to all longitudinal edges of joins between modules,

the screws must be tightened finally, starting with the joints between benches around the

contour, and continuing towards the vertical, advancing by level and contour. See

tightening torque by position and metric dimension.

THREAD

TIGHTEHINGS (Nm)

Steel’s quality

8.8 (8G)

10.9 (10K)

M6

10.5

15

M7

17.5

25

M8

26

36

M10

51

72

M12

89

125

M14

141

198

Apply

here

Summary of Contents for DFLEX 1100

Page 2: ...DFLEX Assembly instructions 2...

Page 16: ...DFLEX Assembly instructions 16 The following result is obtained...

Page 29: ...DFLEX Assembly instructions 29 DFLEX 1100 400V 5...

Page 30: ...DFLEX Assembly instructions 30 DFLEX 1100 440 480V NOT WIRING...

Page 31: ...DFLEX Assembly instructions 31 DFLEX 1300 400V 5...

Page 32: ...DFLEX Assembly instructions 32 DFLEX 1300 460V 5 NOT WIRING...

Page 33: ...DFLEX Assembly instructions 33 DFLEX 1700 400V 5...

Page 34: ...DFLEX Assembly instructions 34 DFLEX 2100 400V 5...

Page 35: ...DFLEX Assembly instructions 35 DFLEX 2100 460V 5 48 Elementos NOT WIRING...

Page 36: ...DFLEX Assembly instructions 36 DFLEX 2100 460V 5 45 elements Requires SSR in E4 NOT WIRING...