®

5

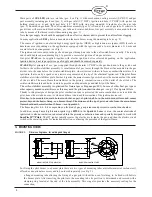

7. INSTALLATION

During the installation, all components have to be protected from impact or bending.

WARNING: DURING PILOT INSTALLATION THE RECOMMENDATIONS IN THE

APPENDIX 2 SHOULD BE STRICTLY OBSERVED.

SP-48-FD

pilot’s air tube

can be welded directly to the burner plate, or placed in the mounting tube (see Fig. 2).

It should be noted that the distance from the gas head with mounting ring to the burner plate should be not less than

150 mm and insertion depth cannot exceed the “L” value – see Fig. 1.

Pilot air tube is made of stainless steel, mounting tube is made of carbon steel which must be noted for welding.

Note: Particulates entrained in the gas could block the pilot’s gas orifices so gas supply line should be equipped

with an effective strainer unit.

WARNING: STRICTLY OBSERVE THE TEMPERATURE LIMITS FOR PILOT

AND IGNITER ROD MOUNTED INSIDE. IN THE CASE OF EXPECTED WORK AT

THE LIMIT OF PERMISSIBLE OPERATING TEMPERATURES, APPROPRIATE

MEASURES SHOULD BE TAKEN (E.G. CHANGE OF THE MOUNTING POSITION).

WHEN BOILER OR HEATER INSTALLATION IS IN OPERATION ALWAYS KEEP

THE PROPER AIRFLOW OF PILOT COMBUSTION-COOLING AIR.

7.1 MOUNTING TUBE

The mounting tube, if used, should be attached to the burner plate using bolts or welding (see Fig. 2). If it is not

possible to use one of mounting tubes proposed above, a different type can be used, bearing in mind that its inner

diameter should be properly matched to the outer diameter of the pilot air tube to be able to fit and fix the pilot in

a tube with proper clearance.

In the case of application including a mounting tube proceed the following way:

a)

Based on assembly drawings mark and cut a hole in the burner plate with a diameter slightly larger than

the diameter of the mounting tube.

b)

The mounting tube for welding: slide the mounting tube in the hole and set it in the correct position

(insertion depth and proper angle relative to the main burner nozzle position).

c)

The mounting tube for welding: weld using the electrode appropriate for the material.

d)

If the flanged mounting tube is used, bolt it to the burner plate after drilling the correct sized holes.

7.2 GAS ASSEMBLY AND AIR TUBE

a) The position of the electric igniter rod tip in relation with the orifice-stabilizer assembly of pilot should be

checked following information in p. 4. The correct position for different types of electrical igniter rods

should be taken into consideration (see Fig. 1).

It should be remembered that the rod tip positioning against the swirler-stabilizer plate in the pilot gas part

assembly (pos. 1 on Fig.1) should be done outside the air tube only.

Only after proper rod positioning should the rod be fixed by tightening the gland and the whole gas

assembly with rod inserted into the air tube.

b)

Mounting of electrical igniter rod in a pilot: unscrew the rod tip, disassemble the gland, put all gland

parts on rod, insert the rod in gas head, screw back the rod tip and then set the appropriate tip

position relative to an orifice-stabilizer assy. Now the gland can be screwed onto gas head tightly

. In

case of problems sliding the rod

through rings of fixing

gland apply a small amount of high temperature

resistant grease or grind slightly the gland ring inner surface.

After setting the correct rod position, fasten the rod fixing gland in the gas head. Then the complete gas part

assembly can be slid into the air tube.

Do not remove the rod from fixing gland if it is not necessary, as the gland rings once clamped on rod do

not allow easy rod movement.

.