14

®

APPENDIX No 3

Proposal Data Sheet

SureFire II

™

Pilot

- Forced Draught Gas Pilot

Type

SP-48-

NG/PG-

FD-xxx

Please provide the following data before placing the Order for gas pilot:

1.

Information about End User

—

Plant Name:

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

—

Owner:

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

—

Country:

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

—

Localization (address):

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.

Gas pilot mode of operation:

(check the proper box)

—

intermittent light-off

—

continuous pilot

3.

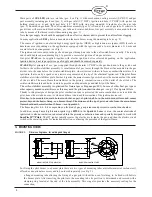

Insertion length “L”:

(see Fig. 1)

. . . . . . . . . . . . .

[m]

4.

Fuel gas for pilot:

—

Natural Gas, Propane Gas, other Fuel Gas:

(check the proper box)

NG PG FG

—

if other Fuel Gas

– specify the type of gas:

enclose gas composition sheet

. . . . . . . . . . . . . . . . . . . . . . . . .

5.

Gas net calorific value:

. . . . . . . . . . . . .

[MJ/Nm

3

]

6.

Required pilot heat input (capacity) at

pressure:

. . . . . . . . . . . . .

[kW]

at [kPa]

7.

Gas pressure range available for pilot:

. . . . . . . . . . . . .

[kPa]

8.

Main burner nominal (or max.) capacity:

capacity of burner to be lit

. . . . . . . . . . . . .

[kW]

9.

Air for pilot:

cooling and combustion air

—

air pressure:

. . . . . . . . . . . . .

[kPa]

—

air flow:

. . . . . . . . . . . . .

[m

3

/min]

Remarks: The reasons why the gas composition information is so important in case of other Fuel gases used:

1. Use of other Fuel Gases like: coke oven gas, blast furnace gas, biogas and especially refinery gas (Refinery

Off Gas) needs additional engineering and testing because their gas compositions and calorific values are

different than these of NG, PG and LPG taken for gas pilot design. Moreover they can vary considerably

from one plant to another and also change a lot over time.

2. Refinery Off Gas (ROG):

is a mixture of gases generated during the processing of crude oil in the refinery.

Such recovery gases have common components such as hydrogen, methane, ethane, butane, propane and ethylene

and are used as a fuel to produce energy to run the refinery processes.

An ROG contains many additional components such as oxygen, ammonia, nitriles, acetylenes, heavy sulfur

compounds, butadiene, chlorides, arsenic, mercury, vanadium and water, in addition to the acid gases H

2

S, CO

2

,

and COS. Many of them are harmful to the environment.

High contents of H

2

- over 50%, presence of H

2

S or vanadium can cause significant problems during

combustion, especially high temperature corrosion of pilot, igniter and combustion chamber metal parts.

3. For this reason, every pilot’s application where such Fuel gas is used requires careful analysis of the pilot

construction and often functional tests on similar gases.