8

®

9. OPERATION

After installing and completion of pilot start up and tests

SP-48-

NG/PG-

FD

is ready for operation.

General description of activities performed by the burner/boiler control system or manually by operator:

9.1 Preparation of the furnace/boiler for firing up.

9.2 Opening of air to the burner and pilot.

9.3 Preparation of gas installation for operation.

9.4 Setting the gas pressure at the correct level.

9.5 Starting of pilot trial for ignition sequence performed by the controller or in some cases by the operator:

a)

The correct setting of the main burner combustion air.

b) Checking the interlock conditions before firing up.

c) Providing power to the ignition source.

d) Optionally, carrying out the gas line leakage test.

e) Closing the purge valves and opening of gas shut off valves.

f)

The ignition should take place within the time specified by the standards, which should be confirmed

by the relay output of the flame detector.

g) Electrical igniter power off after confirming the presence of the pilot flame, closing the pilot shut off

valves (in case of continuous pilot operation they stay open).

h)

In case of the absence of the flame after trial for ignition - the valves are closed and electrical igniter is

switched off.

i)

Eventual repeating of trial for ignition sequence (depends on the application). Details of sequence,

timings are dependent on application and applicable standards.

In the case of a manually controlled gas pilot, the operator has to close the gas supply to the pilot himself at the

right time if the flame is not detected.

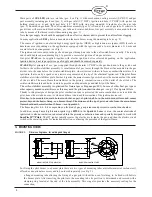

10. SERVICE, MAINTENANCE AND REPAIRS

To remove the igniter for inspection or repair the gas and electrical supply must be shut off first. Checks that the gas

and air manual shut off valves are closed and that the power for ignition device is disconnected.

WARNING

:

DO NOT PERFORM ANY MODIFICATIONS TO THIS EQUIPMENT

AND NEVER USE UNAUTHORIZED SPARE PARTS AS THIS WOULD RESULT IN

A BREACH OF THE ATEX CERTIFICATES CONDITIONS AND COULD PROVE

HAZARDOUS TO YOUR HEALTH AND LIFE !

WARNING

: WHEN THE HEATER/BOILER IS IN OPERATION, DURING SERVICE

WORKS ON BURNER INSTALLATION ALWAYS USE PROTECTIVE PPE CLOTHING,

GLOVES AND GOGGLES !

REMARK

: EVERY 12 MONTHS MAKE AN INSPECTION OF AIR TUBE. IF YOU SEE

ANY TRACES OF EXCESSIVE TEMPERATURE DURING OPERATION INCREASE THE

COOLING-COMBUSTION AIR FLOW OR RETRACT THE GAS PILOT A LITTLE FROM

THE COMBUSTION CHAMBER. IF INCREASING THE AMOUNT OF AIR REMEMBER

THAT IT MAY IMPACT THE FLAME QUALITY.