Page 12

Translation of the original instructions with assembly instructions AF 172 G2, Filtration Group GmbH, 09.12.17, Mat. No. 70355433, Version 05

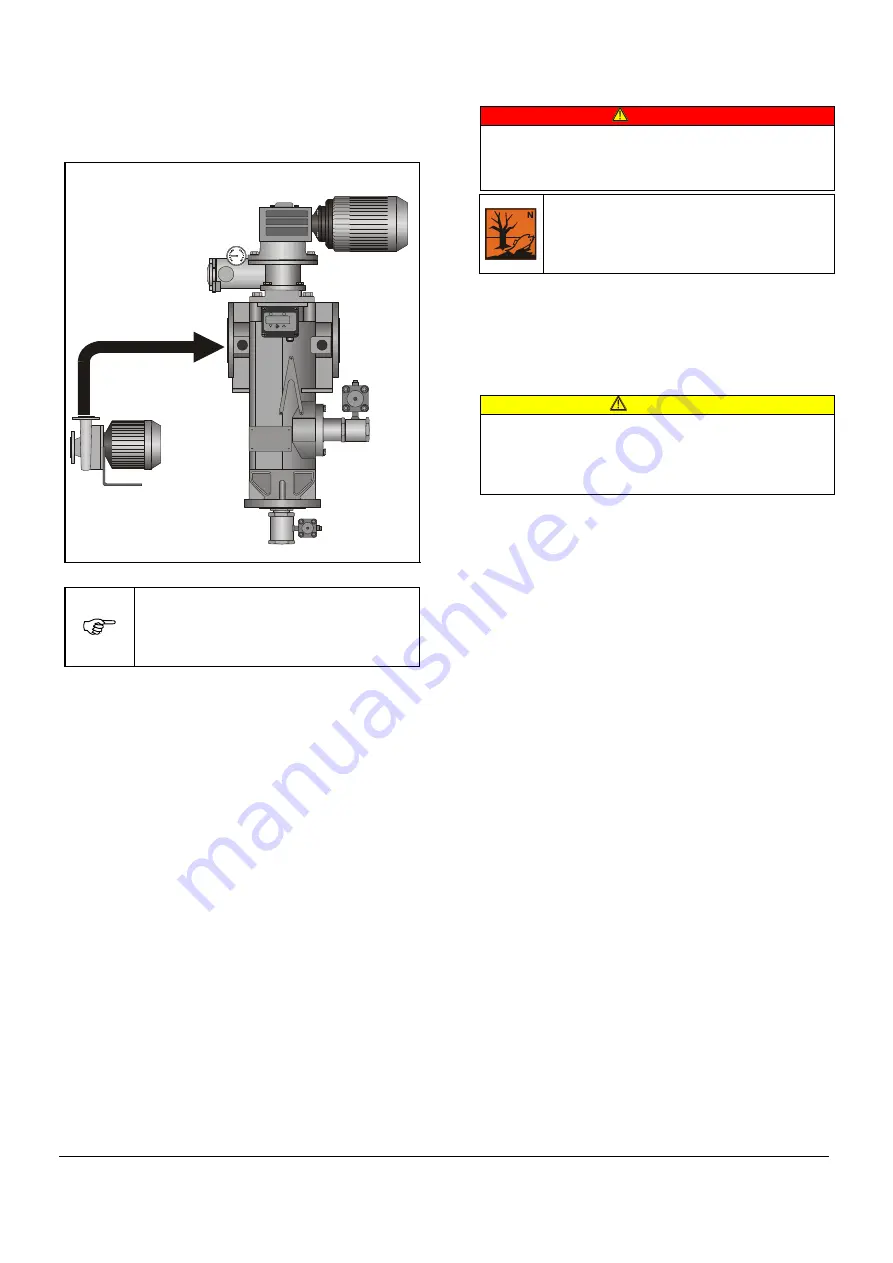

Initial differential pressure

The initial differential pressure varies according to the

application.

General guide:

Installation on discharge side: delta p

≤

0.1 bar

1

2

bar

kPa

psi

Fig. 11:

Initial differential pressure

After a cleaning cycle, the differential

pressure must return almost to the original

initial differential pressure.

If it does not, the cleaning function is faulty (in

this case, please consult the manufacturer).

11

Normal operation

DANGER!

Danger due to high pressure in the automatic filter!

Risk of injury to persons or damage to property

•

Do not allow concentrate to spatter into the

atmosphere!

Always dispose of concentrate in a manner

which does not pollute the environment!

Consult the responsible authorities before

deciding upon the most suitable disposal

method.

The following must be monitored daily during normal

operation:

•

Differential pressure

•

Controller functions

To rinse the drain line

CAUTION!

A high proportion of fine dirt particles in a long pipe

can lead to clogging!

Risk of injury to persons or damage to property

•

Rinse the drain line daily / weekly, depending on the

application.

•

Open the drain valve manually for approx. 10 - 15 s.

The drain line is rinsed

.

12

Shutting down the automatic filter

12.1 Temporary shut-down

On the installed automatic filter controller:

•

Switch OFF the main switch.

12.2 Prolonged shut-down (> 48 h)

•

Start a cleaning process manually.

•

Remove the filter insert (section 15.6).

•

Clean the filter insert (section 15.8.1).

•

Reinstall the filter insert.

•

Fill the automatic filter completely with liquid.

•

Switch OFF the main switch.

12.3 Emergency shut-down

•

Switch OFF the main switch.

The power supply is interrupted.

13

Notes on cooling lubricant filtration

•

Do not attempt to filter magnetic chips. Exercise caution

when grinding grey cast iron or steel.

•

Install a suitable preseparator (800 - 1000 µm).

•

Treat the cooling lubricant carefully. Take steps to

prevent excessive bacterial or fungal attack.

•

Cooling lubricant that has been used for the cleaning

process must be treated separately. There is a risk of

enrichment with fine dirt if it is returned to the cooling

lubricant cycle.

•

Provide a constant-pressure valve in the drain line if the

pressure on the filtered fluid side varies between 4 and

16 bar. The rinsing effect is impaired if the pressure

difference is too high during the cleaning process.

Filter discharge

side