4

Product overview

4.1

Scope of delivery

Component

Number

Servo drive CMMT-AS-...

1

Operating instructions CMMT-AS-...

1

Tab. 6: Scope of delivery

4.2

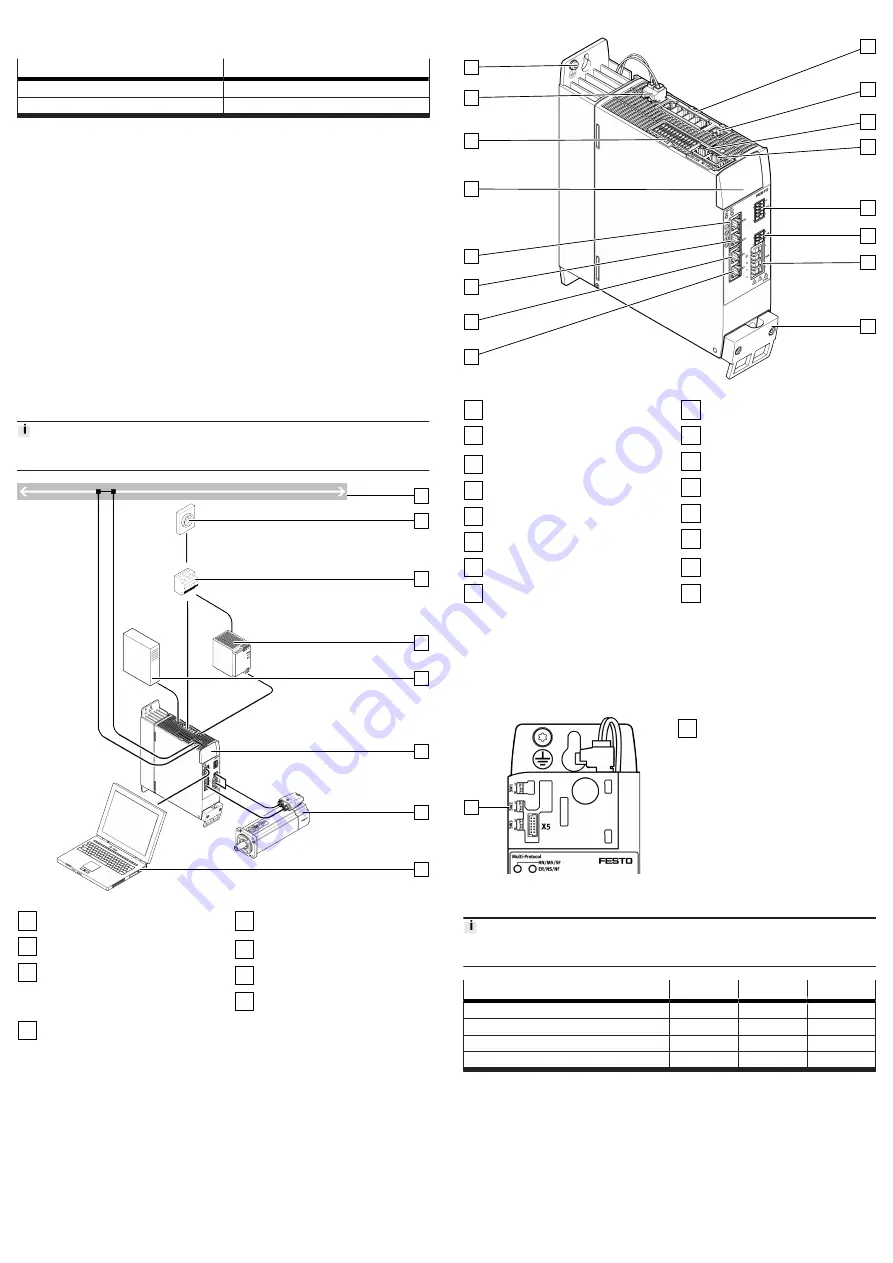

System structure

The servo drive CMMT-AS is a 1-axis servo drive. Depending on the product

variant, the following components, which are necessary for standard applications,

are integrated into the device or into the cooling profile of the device:

–

Mains filter (guarantees immunity to interference and limits conducted emis-

sions)

–

Electronics for DC link voltage conditioning

–

Power stage (for motor control)

–

Braking resistor (integrated into the cooling element)

–

Brake chopper (switches the braking resistor in the DC link circuit, if and when

required)

–

Temperature sensors (for monitoring the temperature of the power module and

of the air in the device)

–

Fan in the cooling profile (depending on product variant)

The servo drive features a real-time Ethernet interface for process control. Var-

ious bus protocols are supported depending on the product design (EtherCAT,

EtherNet/IP or PROFINET).

The device can be parameterised via a PC using either the real-time Ethernet

interface or the separate standard Ethernet interface.

Festo recommends use of servo motors, electromechanical drives, lines and

accessories from the Festo accessory programme.

1

2

3

4

5

6

7

8

Fig. 1: System structure (example)

1

Bus/network

2

Main switch

3

Automatic circuit breaker/fuses

and all-current-sensitive RCD

(residual current device)

(optional)

4

Fixed power supply for logic

voltage supply 24 V DC (PELV)

5

External braking resistor

(optional)

6

Servo drive CMMT-AS

7

Servo motor (here EMME-AS)

8

PC with Ethernet connection for

parameterisation

4.2.1

Overview of connection technology

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Fig. 2: Connections of the CMMT-AS-C2-11A-P3 (example)

1

PE connection, housing

2

[X9A] Mains and DC link circuit

connection

3

[X9C] Logic voltage

4

[XF2 OUT] RTE interface port 2

5

[XF1 IN] RTE interface port 1

6

[X1C] inputs/outputs for the axis

7

[X6B] motor auxiliary connection

8

[X6A] motor phase connection

9

Shield clamp of motor cable

10

[X2] encoder connection 1

11

[X3] encoder connection 2

12

[X10] device synchronisation

13

[X18] standard Ethernet

14

[X5] connection for operator unit

(behind the blind plate)

15

[X1A] I/O interface

16

[X9B] connection for braking

resistor

4.3

Set bus protocol

The CMMT-AS-...-MP product variant supports several bus protocols.

The following options are available for setting the protocol:

–

automatic detection by the CMMT-AS-...-MP

–

Configuration in the CMMT-AS plug-in

–

direct specification via SW1 to SW3

1

Fig. 3: Switches SW1, SW2, SW3 with

the CMMT-AS-...-MP

1

Switches SW1, SW2, SW3

Protocols supported by the firmware version used

è

Manual/online help plug-in,

software, function, fieldbus, device profile.

Protocol

Size 3

Size 2

Size 1

Auto (detection or parameterisation)

0

0

0

PROFINET

0

0

1

EtherCAT

0

1

0

EtherNet/IP

0

1

1

Tab. 7: Switch setting bus protocol

The switches can be adjusted with a small slotted head screwdriver.

The switch position is evaluated once when the device is started.

4.4

Safety sub-functions

4.4.1

Function and application

The servo drive CMMT-AS-...-S1 has the following safety-related performance fea-

tures:

–

Safe torque off (STO)

–

Safe brake control (SBC)