8.3

Commissioning steps

NOTICE

Unwanted drive movements or damage to components.

Incorrect parameterisation may result in unwanted drive movements or overload

when the closed-loop controller is enabled or may lead to connected components

becoming overloaded or damaged.

• Do not enable the closed-loop controller until the configured components

(servo drive, motor, axis, etc.) match those that are connected exactly.

During initial commissioning with the Festo Automation Suite with the CMMT-AS

plug-in installed, the following steps must be performed, for example:

1. Perform configuration and parameterisation with the CMMT-AS plug-in (hard-

ware configuration, critical limits and parameters).

2. If the safety function is being used, check functioning of the safety functions

è

Manual Safety sub-function.

3. Check signal behaviour of the digital inputs/outputs (e.g. limit/reference

switch).

4. Provide required control signals.

5. Check direction of rotation/direction of travel of the electromechanical drive

(e.g. in jog operation).

6. Carry out homing.

7. Test positioning behaviour (test mode,

è

help for the CMMT-AS plug-in).

8. If necessary, optimise controller setting (optional,

è

help for the CMMT-AS

plug-in).

9. Perform fieldbus configuration and test control profile (

è

description of the

device profile used).

10. Complete commissioning (e.g. save project with Festo Automation Suite and

archive project).

9

Operation

Check the safety functions at adequate intervals for proper functioning. It is the

responsibility of the operator to choose the type and frequency of the checks

within the specified time period. The manner in which the test is conducted

must make it possible to verify that the safety device is functioning perfectly in

interaction with all components. Time period for cyclical test

data, safety engineering.

The CMMT-AS is maintenance-free during its period of use and specified service

life. The test interval varies from one safety sub-function to another:

–

STO: no test has to be carried out during the period of use, but we recommend

evaluating STA whenever the sub-function is requested to ensure maximum

diagnostic coverage and the highest safety-related classification.

–

SBC: cyclical test required at least once every 24 h and SBA evaluation rec-

ommended whenever the sub-function SBC is requested to ensure maximum

diagnostic coverage and the highest safety-related classification.

10

Maintenance and care

If used as intended, the product is maintenance-free.

10.1

Cleaning

WARNING

Risk of injury from electric shock.

Contact with live parts at the power connections [X6A], [X9A] and [X9B] can result

in severe injuries or death.

• Do not pull out power supply plugs while live.

• Before touching, wait at least 5 minutes after switching off the load voltage to

allow the intermediate circuit to discharge.

•

Clean the outside of the product with a soft cloth.

11

Malfunctions

11.1

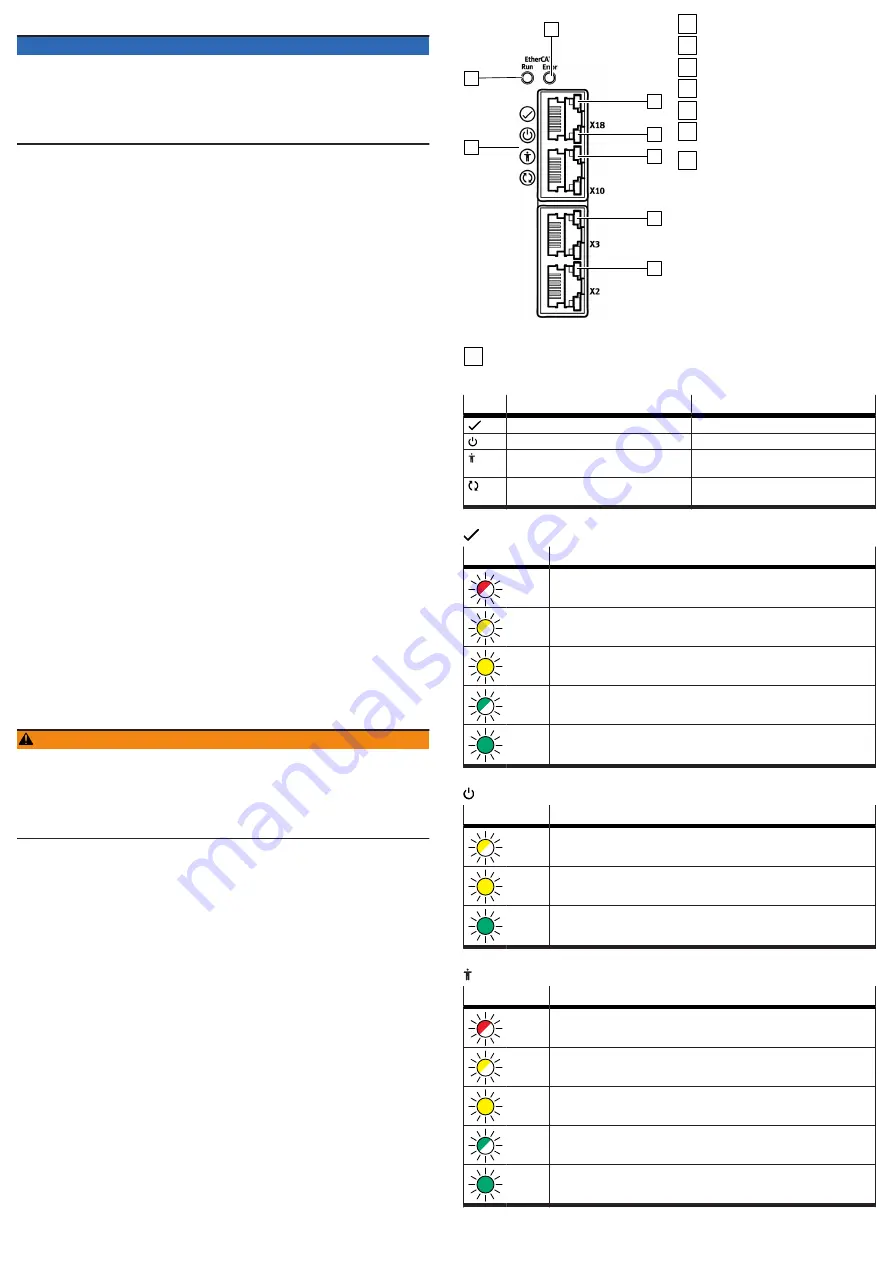

Diagnostics via LED

On the front and top of the device, there are some LEDs for indicating status

information. The number of LEDs depends on the product design. Up to 11 LEDs

are located on the front of the device. Up to 4 LEDs are located on the top of the

device at the connections [X19], XF1 IN and XF2 OUT.

The following image shows an example of the LEDs on the front of product variant

CMMT-AS-...-EC. The labelling and function of the Run LED and Error LED vary

according to the product variant.

1

2

3

4

5

6

7

8

Fig. 11: LEDs on the front

1

Device status (4 LEDs)

2

Run (example CMMT-AS-...-EC)

3

Error (example CMMT-AS-...-EC)

4

Ethernet interface activated [X18]

5

Communication activity [X18]

6

Sync interface activated [X10]

7

Encoder status, encoder interface

[X3]

8

Encoder status, encoder interface

[X2]

11.1.1

Device status displays

LED

Designation

Brief description

Status LED

Indicates the general device status

Power LED

Indicates the status of the power supply

Safety LED

Indicates the status of the safety equip-

ment

Application status LED

Indicates the identification sequence and is

reserved for future extensions

Tab. 45: Device status LEDs (status, power, safety and application status LEDs)

Status LED, display of the device status

LED

Meaning

Flashes

red

An error is present.

Flashes

yellow

A warning is present, or the servo drive is currently performing a firmware

update.

Illumi-

nated

yellow

The servo drive is in the initialisation phase.

Flashes

green

The servo drive is ready, and the power stage is switched off (Ready).

Illumi-

nated

green

The power stage and the closed-loop controller are enabled.

Tab. 46: Status LED

Power LED, status of the power supply

LED

Meaning

Flashes

yellow

The logic voltage and AC supply are present. The intermediate circuit is being

charged.

Lights

up

yellow

The logic voltage supply is present, but the AC supply is lacking.

Lights

up

green

The logic voltage supply is present, and the intermediate circuit is charged.

Tab. 47: Power LED

Safety LED, status of the safety engineering

LED

Meaning

Flashes

red

Error in the safety part or a safety condition has been violated.

Flashes

yellow

The safety sub-function has been requested but is not yet active.

Illumi-

nated

yellow

The safety sub-function has been requested and is active.

Flashes

green

Power stage, brake outputs and safety diagnostic outputs are blocked (safety

parameterisation is running).

Illumi-

nated

green

Ready, no safety sub-function has been requested.

Tab. 48: Safety LED