3.10 Maintenance work

3.10.1 Preliminary remarks

Always carry out the prescribed maintenance

work and maintenance measures on time in

order to maintain the safety, operational readi-

ness and long service life of the machine.

The machine must only be serviced by quali-

fied personnel authorised by the operating

company.

3.10.2 Working on hydraulic lines

Before the hydraulic system can be depressur-

ized, machine parts with hydraulic movement

must be safely set down or secured to prevent

them from falling.

Relieve hydraulic pressures before working on

hydraulic lines. Hydraulic oil escaping under

pressure can penetrate the skin and cause

severe injury. Immediately call for medical

assistance if injured by hydraulic oil.

Do not step in front of or behind the machine

when performing adjustment work in the

hydraulic system.

Do not change the setting of pressure relief

valves.

Drain the hydraulic oil at operating temperature

– danger of scalding!

Any hydraulic oil must be collected and dis-

posed of in an environmentally friendly way.

Always collect and dispose of hydraulic oils

separately.

Do not start the engine after draining off the

hydraulic oil. Once all work is completed (with

the system still depressurized!) check all con-

nections and fittings for leaks.

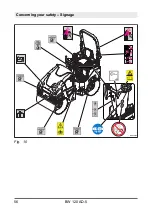

Concerning your safety – Maintenance work

BW 120 AD-5

50

Summary of Contents for BOMAG BW 120 AD-5

Page 9: ...1 Introduction Introduction BW 120 AD 5 9 ...

Page 13: ...2 Technical data Technical data BW 120 AD 5 13 ...

Page 19: ...3 Concerning your safety Concerning your safety BW 120 AD 5 19 ...

Page 62: ...Machine type plate example Fig 29 Concerning your safety Signage BW 120 AD 5 62 ...

Page 64: ...Concerning your safety Danger zones BW 120 AD 5 64 ...

Page 65: ...4 Indicators and control elements Indicators and control elements BW 120 AD 5 65 ...

Page 80: ...Indicators and control elements Engine compartment BW 120 AD 5 80 ...

Page 81: ...5 Checks prior to start up Checks prior to start up BW 120 AD 5 81 ...

Page 96: ...Checks prior to start up Checking the hydraulic oil filter BW 120 AD 5 96 ...

Page 97: ...6 Operation Operation BW 120 AD 5 97 ...

Page 122: ...Operation Emergency procedures BW 120 AD 5 122 ...

Page 123: ...7 Loading transporting the machine Loading transporting the machine BW 120 AD 5 123 ...

Page 132: ...Loading transporting the machine Folding down and erecting the foldable ROPS BW 120 AD 5 132 ...

Page 133: ...8 Maintenance Maintenance BW 120 AD 5 133 ...

Page 190: ...Maintenance As required BW 120 AD 5 190 ...

Page 191: ...9 Setting up refitting Setting up refitting BW 120 AD 5 191 ...

Page 194: ...Setting up refitting Manually adjusting the crabwalk BW 120 AD 5 194 ...

Page 195: ...10 Troubleshooting Troubleshooting BW 120 AD 5 195 ...

Page 206: ...Troubleshooting Trouble shooting ECONOMIZER BW 120 AD 5 206 ...

Page 207: ...11 Disposal Disposal BW 120 AD 5 207 ...

Page 209: ......

Page 210: ......