www.fastech-motions.com - 27

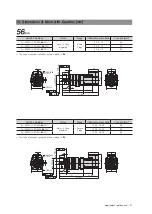

◆ CW, CCW Input

This signal can be used to receive a positioning pulse

command from a customer host motion controller.

The customer can select 1-Pulse Input mode or 2-Pulse

Input mode(refer to switch No.1, SW 1). The input schematic of

CW, CCW is designed for 5V TTL level. When using 5V level

as an input signal, the resistor Rx is not used and connect to

the drive directly. When the level of input signal is more than

5V, Rx resistor is required. If the resistor is absent, the drive

will be damaged! If the input signal level is 12V, Rx value is

680ohm and 24V, Rx value is 1.8Kohm.

Pulse input signals of the drive are all photocoupler

protected. The signal shows the status of internal

photocouplers [ON : Conduction],

[OFF : Non-conduction], not displaying the voltage

levels of the signal.

◆ Alarm Reset Input

Release the alarm output of the drive where the protection

function is activated. When the Alarm Reset input is set to

[OFF], the alarm output is canceled. Remove the cause of the

alarm before releasing the alarm output. If the cause of the

alarm is not removed, the Alarm Reset input will not operate

normally even if it is set to [OFF].

※ By setting the alarm reset input signal [ON], cancel the Alarm

output. Before cancel the Alarm output, have to remove the source

of alarm.

◆ Servo On/Off Input

This input can be used only to adjust the position by manually

moving the motor shaft from the load-side. By setting the

signal [LOW], the drive cuts off the power supply to the motor.

Then, one can manually adjust output position. When setting

the signal back to [High], the drive resumes the power to the

motor and recovers the holding torque. When driving a motor,

one needs to set the signal [High].

Servo On / Off and Alarm Reset of the drive are

operated with voltage level [ON : High] and [OFF : Low].

Alarm and In-Position signals of the drive are operated

by [ON : Conduction] and [OFF : Non-conduction] of

open-drain circuit.

Input Signal

1

Output Signal

2

◆ Alarm Output

The Alarm output indicates [ON] when the drive is in a normal

operation. If a protection mode has been activated, it goes

[OFF]. A host controller needs to detect this signal and stop

sending a motor driving command. When the drive detects

an abnormal operation such as overload or over current of

the motor, it sets the Alarm output to [OFF], flashes the Alarm

LED, disconnect the power to a motor and stops the motor

simultaneously.

◆ In-Position Output

The In-Position output is used to send motor motion to the

host controller. When the movement of the motor is completed,

the In-Position output becomes [ON].

In-Position output is [ON] when the motor stops within the

position deviation set value.

Pin No.

Function

11

CW+

12

CW-

9

CCW+

10

CCW-

※ Please use the input voltage

5-24VDC. If the input is not

connected, it is in the High state.

If the input voltage is less than

0.6V, it is the Low state.

Ω

Ω

Pin No.

Function

7

Servo On/Off

8

Alarm Reset

Pin No.

Function

5

Alarm

6

In-Position

18. Control Signal Input/Output Description [Ezi-SERVOⅡ-BT-28 series]