32

The

Job Queue

tab appears only when a print job is

being sent to the printer. This tab tells you the

name and status of each job in the queue and shows

you the order in which the jobs will print if you

have sent multiple jobs to the printer. A control

button is also provided which allows you to delete

every job listed in the queue. To delete the job

currently being printed, simply select the Cancel

Print button under the Current Job tab.

C. Setting Up

the Windows

Printer Driver

Once the printer driver has been successfully

installed, you will need to set the driver up for the

particular card size and type of ribbon you have

installed in the printer. There are also several

additional options that can be selected. Use the

following steps to select the appropriate printer

driver settings:

1.

If using Windows 3.1x, go back to the Control

Panel and the Printers group using steps 1 and 2 on

pages 27 and 28. If using Windows 95, Click the

Start

button, point to

Settings

, and select

Printers

.

Then, click on the

Color ID Card II

icon with the

right mouse button and select

Properties

. The

Properties window will appear.

2.

In Windows 3.1x, select the Setup button. In

Windows 95, click on the Details tab of the

Properties window and select the Setup button.

NOTE

Some applications allow you to change these same

printer driver options from their “Print” and/or “Printer

Setup” screens. This means that you don’t have to go

back to the main printer setup window each time you

want to change a setting or option in the printer driver.

These applications will usually give you the same choices

and options, but in a slightly altered format.

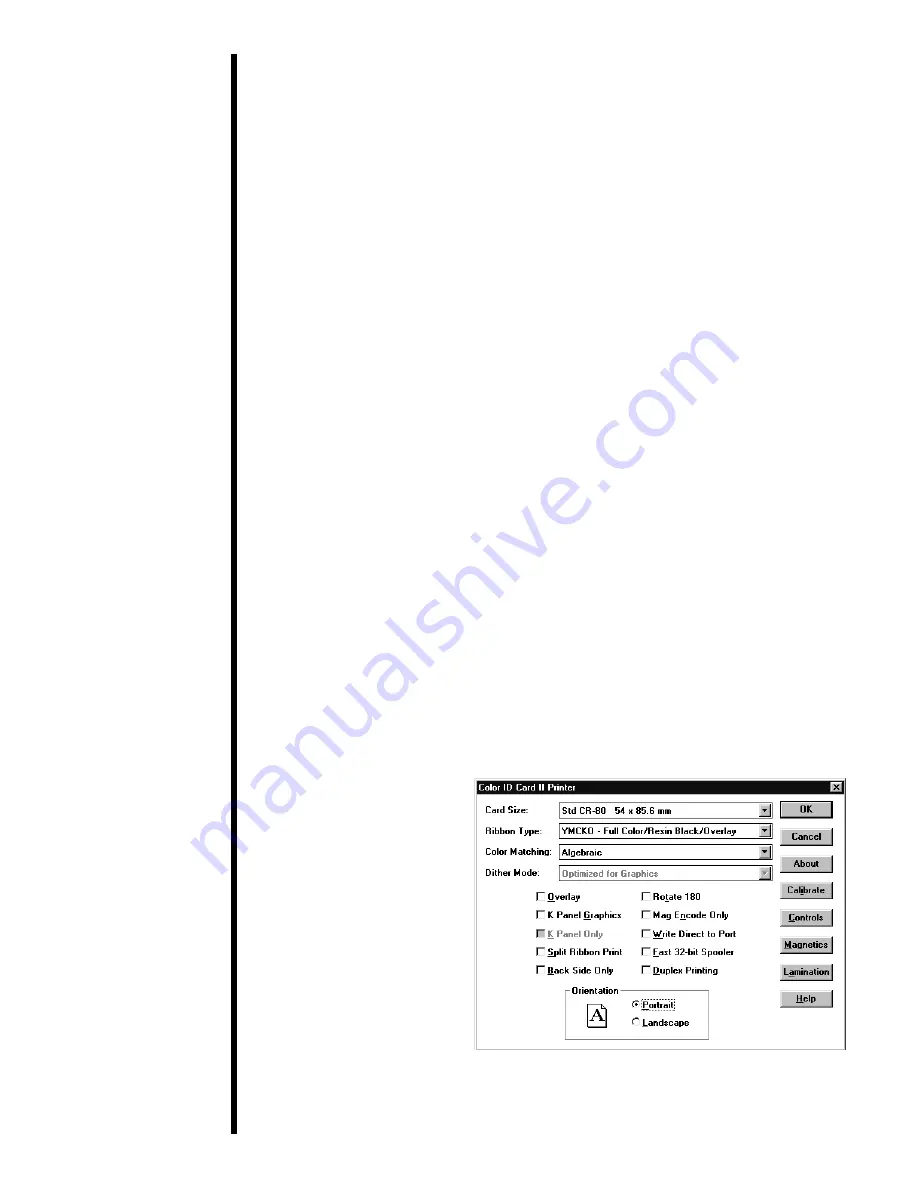

3.

The Color ID Card II

Printer screen appears.

Change the options as

follows: