SPRINT 382 - SPRINT 383

7

00058I0112 - Rev.6

Tr

ansla

tion of the original instruc

tions

ENGLISH

ADVANCED PROGRAMMING F + +

Display

Function

Default

Ph

CLOSING PHOTOCELLS LOGIC:

Select the tripping mode of the closing photocells.

They operate for the closing movement only: they stop move-

ment and reverse it when they are released, or they reverse it

immediately.

Y

= Reverse on release

no

= Reverse immediately when opening

no

oP

OPENING PHOTOCELLS LOGIC:

Select the tripping mode of the opening photocells.

They operate for the opening movement only: they stop the

movement and restart it when they are released, or they reverse

it immediately.

Y

= Reverse immediately when closing

no

= Restart movement on release

no

EC

ENCODER:

If the encoder is used, you may select its presence.

If the encoder is present and enabled, “decelerations” and “partial

opening” are controlled by the encoder (see relevant paragraphs).

The encoder operates as an anti-crushing device: If the gate

strikes an obstacle during opening or closing, the encoder

immediately reverses gate leaf movement for 2 seconds. If the

encoder operates again during the 2-seconds reversing time, it

stops movement (STOP) without commanding any reversing. If

no sensor is supplied, the parameter must be set on

00

. If there

is the encoder, adjust the sensitivity of the anti-crushing system,

by varying the parameter between

01

(maximum sensitivity) and

99

(minimum sensitivity).

From

01

to

99

= Encoder active and sensitivity adjustment

00

= Encoder disabled

00

rP

Pre-limit switch DECELERATION:

You can select gate deceleration before the opening and closing

limit-switches have been tripped.

Time can be adjusted from

00

to

99

.

If an encoder is used, the adjustment is not determined by time

but by motor revs, thus obtaining greater deceleration precision.

00

= Deceleration disabled

from

01

to

99

= Deceleration enabled

10

rA

Post-limit switch DECELERATIONS:

You can select gate deceleration after the opening and closing

limit-switches have been tripped.

Time can be adjusted from

00

to

20

sec. in 0.04-second steps.

If an encoder (optional) is used, the adjustment is not determined

by time but by motor revs, thus obtaining greater deceleration

precision.

00

= Deceleration disabled

from

01

to

20

= Deceleration enabled

05

PO

PARTIAL OPENING:

You can adjust the width of leaf partial opening.

Time can be adjusted from

01

to

20

sec. in 0.1-second steps.

If an encoder (optional) is used, the adjustment is not determined

by time but by motor revs, thus obtaining greater precision of

partial opening.

E.g.

for a gate with a sliding speed of 10 m /min, value

10

corre-

sponds to about 1.7 metres of opening.

E.g.

for a gate with a sliding speed of 12 m /min, value

10

corre-

sponds to about 2 metres of opening.

05

t

WORK TIME:

We advise you to set a value of 5 to 10 seconds over the time

taken by the gate to travel from the closing limit-switch to the

opening limit-switch and vice versa. This will protect the motor

against any overheating if a limit-switch fails.

Adjustable from

0

to

59

sec. sec. in one-second steps.

Subsequently, viewing changes to minutes and tens of seconds

(separated by a point) and time is adjusted in 10 second steps,

up to a maximum value of

4.1

minutes.

E.g.

if the display shows

2.5

, work time is 2 min. and 50 sec.

The set value does not exactly match the motor’s ma-

ximum operating time, because the latter is modi

fi

ed

according to the performed deceleration spaces.

2.0

ADVANCED PROGRAMMING F + +

Display

Function

Default

AS

ASSISTANCE REQUEST (combined with next function):

If activated, at the end of countdown (settable with the next fun-

ction i.e. “Cycle programming”) it effects 2 sec. of pre-

fl

ashing (in

addition to the value already set with the PF function) at every

Open pulse (job request). Can be useful for setting scheduled

maintenance jobs.

Y

= Active

no

= Disabled

no

nc

CYCLE PROGRAMMING:

For setting countdown of system operation cycles. Settable (in

thousands) from

00

to

99

thousand cycles.

The displayed value is updated as cycles proceed.

This function can be used to check use of the board or to exploit

the “Assistance request”.

00

St

GATE STATUS:

Exit from programming and return to gate status viewing (see

Chpt 5.1.).

To reset the programming default settings, check if the edge input is

opened (SAFE LED OFF), and simultaneously press keys

+

,

-

and

F

, holding

them down for 5 seconds.

Modification of programming parameters comes into effect immediately,

whereas definitive memory storage occurs only when you exit program-

ming and return to gate status viewing. If the equipment is powered down

before return to status viewing, all modifications will be lost.

6. START-UP

6.1. INPUTS CHECK

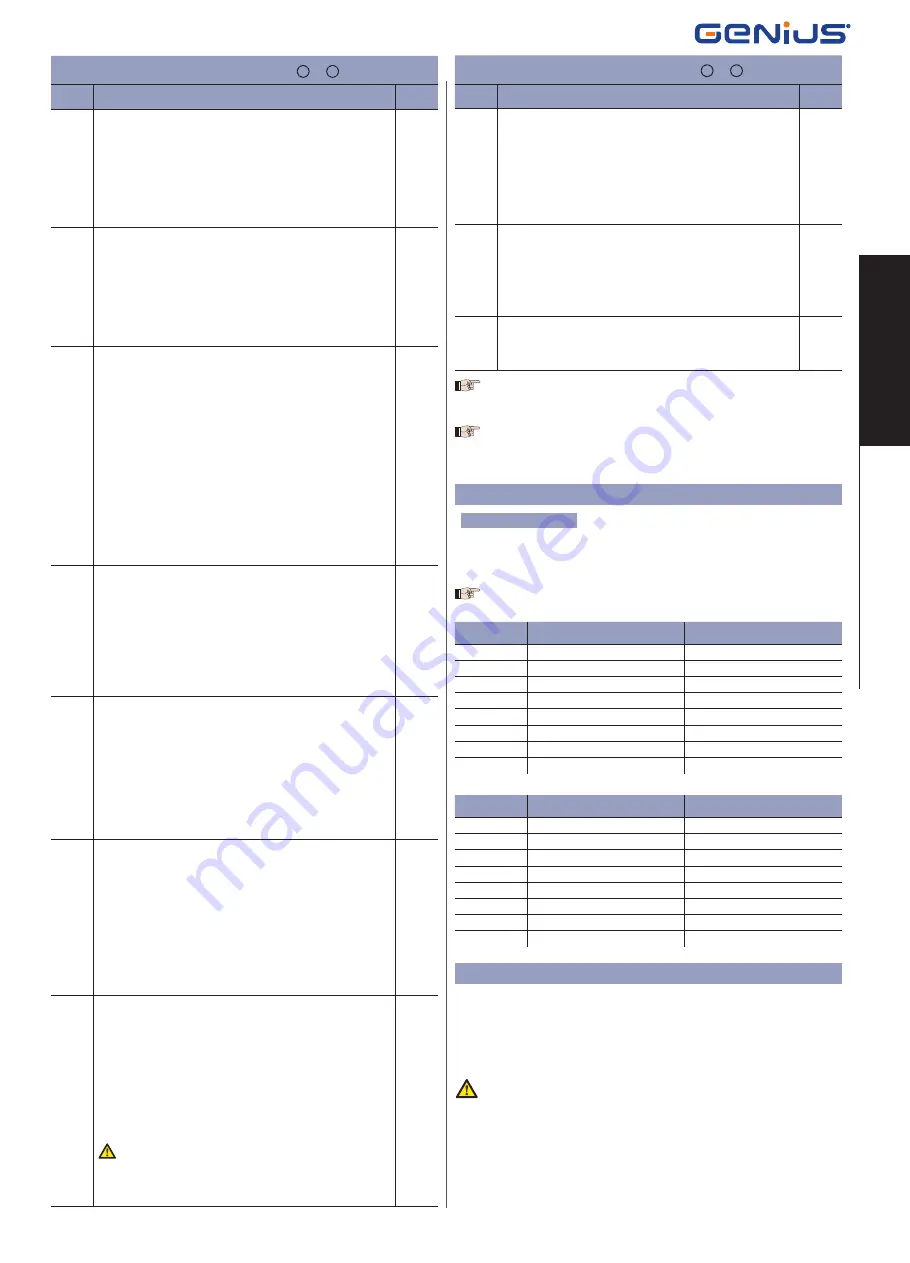

The table below shows the status of the LEDs in relation to to the status of the inputs.

Note the following:

Led lighted

= closed contact

Led off

= open contact

Check the status of the LEDs as per Table.

The status of the LEDs while the gate is closed at rest are shown in bold.

dl = -3

= Right-hand opening movement

LEDS

LIGHTED

OFF

FCA

Limit-switch free

Limit-switch engaged

FCC

Limit-switch free

Limit-switch engaged

OPEN B

Command activated

Command inactive

OPEN A

Command activated

Command inactive

FSW OP

Safety devices disengaged

Safety devices engaged

FSW CL

Safety devices disengaged

Safety devices engaged

STOP

Command inactive

Command activated

EDGE

Safety devices disengaged

Safety devices engaged

dl = 3-

= Left-hand opening movement

LEDS

LIGHTED

OFF

FCA

Limit-switch free

Limit-switch engaged

FCC

Limit-switch free

Limit-switch engaged

OPEN B

Command activated

Command inactive

OPEN A

Command activated

Command inactive

FSW OP

Safety devices disengaged

Safety devices engaged

FSW CL

Safety devices disengaged

Safety devices engaged

STOP

Command inactive

Command activated

EDGE

Safety devices disengaged

Safety devices engaged

7. AUTOMATED SYSTEM TEST

When you have

fi

nished programming, check if the system is operating correctly.

Most important of all, check if the force is adequately adjusted and if the safety devi-

ces are operating correctly. Veri

fi

care soprattutto l’adeguata regolazione della forza

e il corretto intervento dei dispositivi di sicurezza. Make sure it has been adjusted

correctly by using an impact force tester in accordance with standard EN 12453. For

non-EU countries, if there are no speci

fi

c local regulations, the static force must be

less than 150 N.

If the impact force limits indicated in the standard have been met using the

pre-limit switch deceleration, the function

Sr

=

Y

in advanced programming

has to be enabled: every time power is turned on / restored, the leaf moves at

a slow speed until it has travelled completely between one limit switch and

the other.

DECELERATION

- The deceleration is carried out only after a complete cycle has

taken place from one limit switch to the other. Each time the power is turned on/

restored, the cycles carried out before the complete movement take place at normal

or slow speed according to parameter

Sr

in advanced programming.

Summary of Contents for GENIUS Sprint 382

Page 13: ...746 E R 41 732099 Rev D...

Page 14: ......