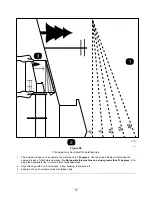

Maintenance

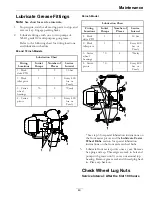

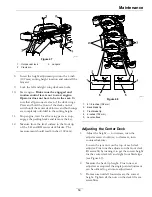

g240665

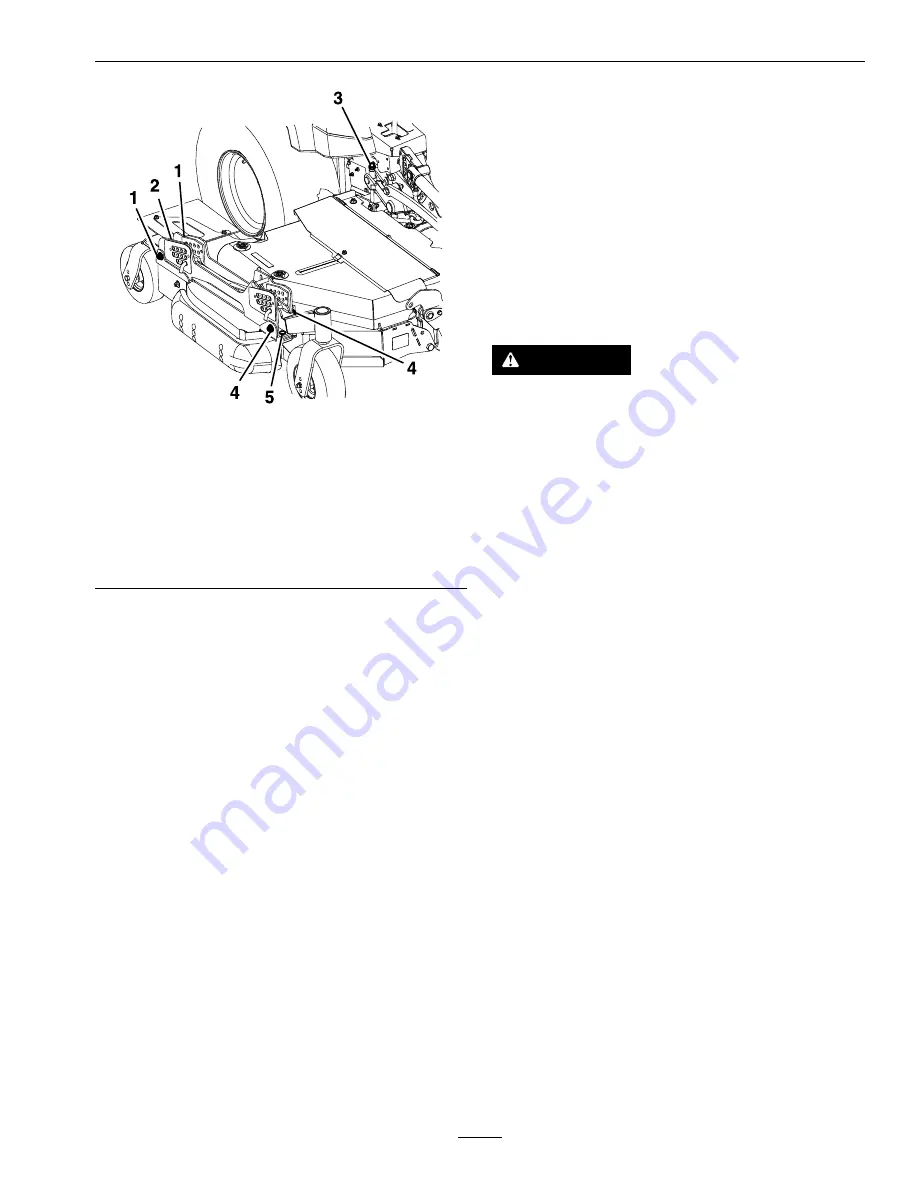

Figure 51

RH Wing Deck Shown

1.

Rear hanger mounting nuts

2.

Rear height adjustment hardware location

3.

Single point rear adjustment

4.

Front hanger mounting nuts

5.

Front height adjustment hardware location

•

If the deck is too low, tighten the front height

adjustment bolt (item 5, Figure 51) by rotating

the bottom nut clockwise.

•

If the deck is too high, loosen the front height

adjustment bolt (item 5, Figure 51) by rotating

the bottom nut counterclockwise. Fine tuned

the rear adjusters as required.

Adjust the rear wheel height (item 2, Figure 51)

so that the rear wheel lightly touches the ground

with minimal pressure.

4.

Measure the back of the wing blades. If either

has less than 1/16 inch (1.5 mm) rake, raise the

back of the deck by tightening the LH and RH

rear adjustments (item 3, Figure 51) until all

four blades have a minimum of 1/16 inch rake

(1.5 mm). Readjust the wing rear wheels so they

lightly touch the ground with minimal pressure.

Tighten all four rear hanger mount points (item

1, Figure 51).

5.

Retighten the front and rear height of cut hanger

jam nuts.

Deck Belt Tension

Self-tensioning - No adjustment necessary.

Parking Brake Adjustment

Service Interval: After the first 100 hours

Every 400 hours thereafter

Check to make sure brake is adjusted properly. This

procedure must be followed after the first 100 hours

or when a brake component has been removed or

replaced.

CAUTION

Raising the mower deck for service or

maintenance relying solely on mechanical

or hydraulic jacks could be dangerous. The

mechanical or hydraulic jacks may not be enough

support or may malfunction allowing the unit to

fall, which could cause injury.

Do Not rely solely on mechanical or hydraulic

jacks for support. Use adequate jack stands or

equivalent support.

1.

Drive the machine onto a level surface.

2.

Disengage the blade control switch (PTO), move

the motion control levers to the neutral locked

position and engage the parking brake (lever is in

the “up” position).

3.

Stop the engine, wait for all moving parts to stop,

and remove the key.

4.

Raise the back of the machine up and support the

machine with jack stands.

5.

Remove the rear tires from the machine.

6.

Remove any debris from the brake area.

7.

Rotate the drive wheel release handle to the

“released” position. Refer to the

Drive Wheel

Release Valves

section in Operation.

8.

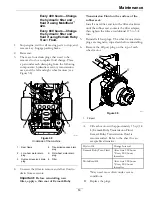

If the link assembly is attached (see Figure 52)

•

in the front position, the length=8.63 inches

(21.9 cm).

•

in the rear position, the length=9.15 inches

(23.2 cm).

9.

The length of the spring should measure 3 1/4

inches (8.3 cm).

10.

Once the spring length is achieved, check to see

if there is a visible gap between the trunion and

the shoulder.

61