22

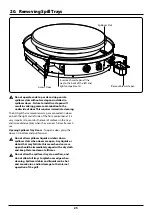

Outer Burner

Control Knob

Inner Burner

Control Knob

Inner Burner

Outer Burner

Inner Burner and Inner Control Knob

- The Inner Gas

Burner is a 7.5” (190mm) in diameter. This burner is controlled

by the Inner or center control knob. Temperatures are

adjustable from Low to High. Starting at the Off position, the

Inner Control Knob rotates 180-degrees counterclockwise

through three positions.

Outer Burner and Outer Control Knob

- The Outer Gas

Burner is a 17” (432mm) in diameter. This burner is controlled

by the Outer or right-hand control knob. Temperatures are

adjustable from Low to High. Starting at the Off position, the

Outer Control Knob rotates 180-degrees counterclockwise

through three positions.

Either the Inner or the Outer burners may be used

independently to support a wide range of cooking

techniques. Operating only the Inner burner provides direct

temperature under the center of the cook surface, with

indirect heat at the outside edge that is useful for holding

temperature and simmering items in a pot or pan.

Conversely, operating only the Outer burner can be used

for cooking foods that may be displayed around the outside

radius of the grill like skewered vegtables and meats. Finally,

with both burners operational, you will have maximum

surface temperature and cooking versatility.

Because the burners are enclosed within a circular chassis

and all heat is directed upward at the cooking surface, cook

surface temperature recovery is very fast, providing a wide

range of surface temperature adjustment and control.

17. 25G Temperature Control

Summary of Contents for AGA AGA-10-0096-LP-CE

Page 31: ......