3

Introduction

The Everpure MRS-200 System is a pre-engineered, pre-assembled reverse osmosis system

designed to provide high purity water for many applications, such as premium espresso, coffee

and blended beverages, to name a few. It combines a number of water treatment technologies

into one easy to install package. The system provides superior protection against taste and odor

causing contaminants while removing dirt, particulates and dissolved solids that can foul or

scale equipment.

Please read this manual prior to installing and operating the system.

Initial Outlet Water Production

200 gal per day (52 Liters per day) @ 60 psig (340 kPa), 77

o

F (25

o

C)

Water production depends on supply water pressure and temperature.

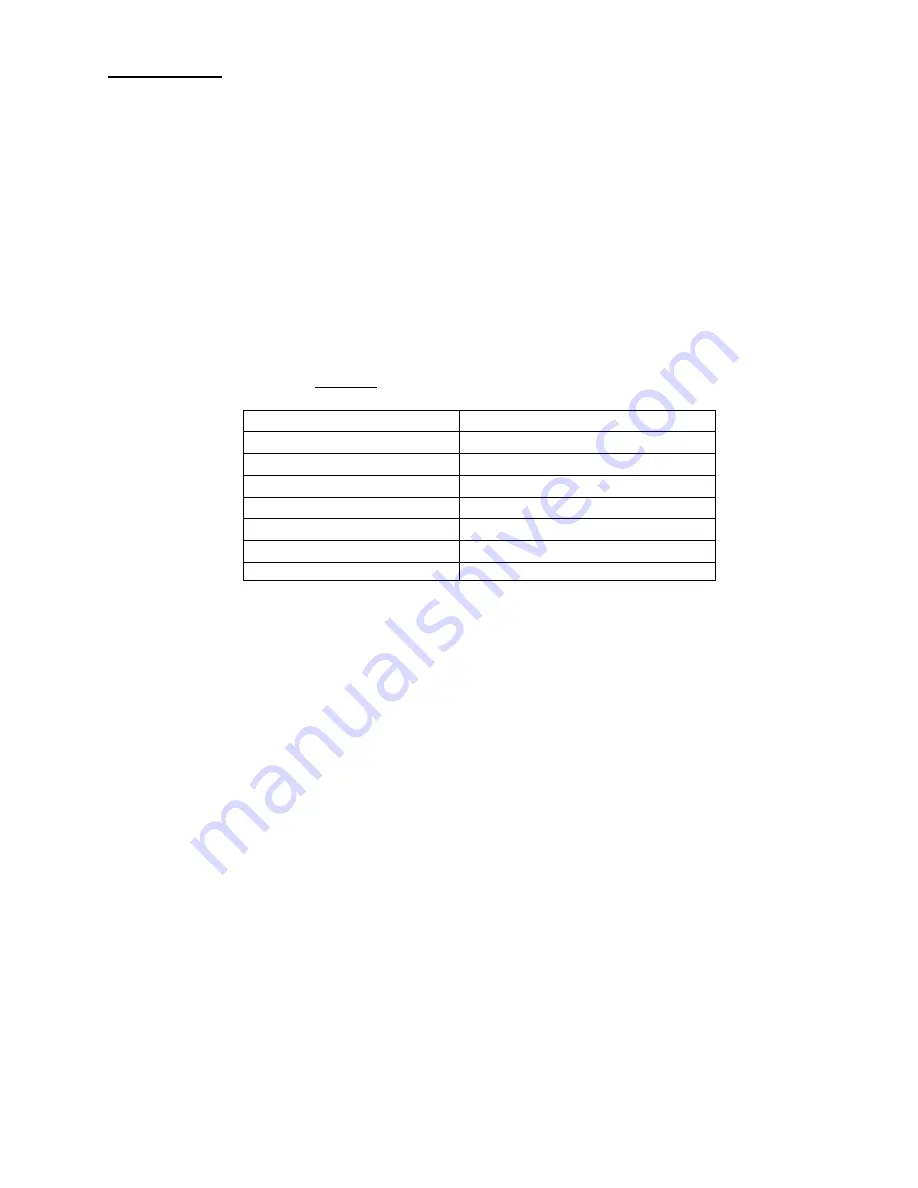

TABLE 1 - Influent Water Characteristics

Pressure

1

60-100 psig (414-690 kPa)

Temperature

33-100°F (1-38°C)

Total Dissolved Solids (TDS)

2

0-2500 PPM (0-2500 mg/L)

pH

5-10

Chlorine

3

0 PPM (0 mg/L)

Chloramine

0-3 PPM (0-3 mg/L)

Turbidity

0-10 NTU

Iron

0-1 PPM (0-1 mg/L)

1.

For units with inlet pressure lower than 50 psig a booster pump is recommended.

2.

Where TDS exceeds 600 PPM (600 mg/L) and the pressure less than 60 psig, a booster pump is recommended.

3.

The reverse osmosis membrane filter used in this system will be damaged by chlorine. An activated carbon filter has

been provided with this system to protect the reverse osmosis membrane from chlorine attack. Influent chlorine

should not exceed 3 mg/L.

The MRS-200 System consists of seven major components:

1. Gallon/Calendar monitor.

2. 5-Micron Pre-filter.

3. Granular Activated Carbon Taste & Odor (TO) cartridge.

4. Reverse Osmosis (RO) membrane cartridge.

5. Filtered Water Blend Valve.

6. 15-gallon atmospheric Storage Tank.

7. Constant pressure product water Re-pressurization Pump.

The MRS-200 contains all the necessary piping, valves and fittings pre-assembled onto a floor-

standing rack. Lengths of ¼” and 3/8” tubing are provided for connecting to the

wastewater/drain and sample/flushing lines.

The 5-micron pre-filter removes suspended particles, which can lead to pre-mature plugging of

the TO and/or RO membrane cartridge(s). The TO cartridge removes most oxidizers, but mainly

reduces chlorine, preventing damage to the RO cartridge. The RO cartridge contains a semi-

permeable reverse osmosis membrane. Here, most dissolved impurities are separated from the

water and flushed down the drain. The water that is able to pass through the membrane, which

is very low in dissolved impurities, enters the

storage tank. This is referred to as RO water or

product water. In certain applications, some filtered water is mixed (via the filtered water blend

valve) with the product water to attain a specific level of total dissolved solids (TDS).

Summary of Contents for MRS-200

Page 19: ...19 Replacement Parts...