Instruction Manual ZHK

94/129

V07-19.0

The corresponding K-factors of the fan are shown in the fan-motor data sheet or on the technical

data sheet for the AHU. The data on the data sheet always refers to one fan.

The air density at the measuring point is to set up manually, depending on sea level, temperature

and humidity. In most cases, 1.2 kg/m³ is a suitable value.

Note:

If in the EUROCLIMA delivery a device for airflow measurement is included, then this must

be configured on site and this is responsibility of the client before, commissioning!

Airflow rate indicator type PREMASREG 7161

This airflow indicator is used by EUROCLIMA and is supplied with the AHU, if included in the

scope of delivery. The setting of the parameters must be made by the customer before commis-

sioning

. This means, it is the client’s responsibility

to complete this task in accordance with the en-

closed instructions of the manufacturer.

The display is programmed according to formula B. Correspondingly, the value kB specified on the

data sheet in the fan section or the technical data sheet for the AHU must be used.

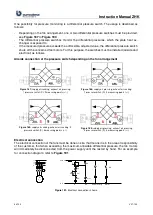

If more than one fan is installed in the supply or exhaust air, then the following instructions must be

observed:

Fan execution

Displays in pcs.

Measuring points

Total air flow rate

2 fans 50 % + 50 %

1 display

Only the fan near-

est to the operating

side

Displayed value * 2

2 fans 100 % + 100 %

2 displays

Both fans sepa-

rately

Displayed value (pow-

ered fan)

>2 fans/fan walls

1 display

Only the fan near-

est to the operating

side

Displayed value * num-

ber of powered fans)

Table 11:

Notes for airflow rate indicators, which are included in the scope of delivery

Processing the pressure signal in other devices

Devices from other manufacturers may require a conversion of the K-value. Therefore, always ask

for the formula, which the device is using.

8.1.3

Heat exchanger

The heat exchangers, fittings and valves shall be tested for tightness.

Attention!

Refrigerant

If direct expansion heat exchangers or air cooled heat exchangers are installed, the system must

be filled with refrigerant after the complete assembly. In this case, a refrigeration engineer must ex-

ecute the installation and piping.

Water heat exchangers

Normal heating, cooling coils filled with water and additives for freeze and corrosion protection:

-

Open vent valve.

-

Water valve is initially only to open slightly, so that the coil will be slowly filled with water. To

avoid heat stress.

-

When the heat exchanger is filled, close the vent valve.

-

Water valve is to open fully, start the fan.

-

Subsequently, the entire piping system must be vented properly.

Summary of Contents for ZHK Series

Page 1: ...ZHK INSTRUCTION MANUAL ...