Pellet store

Filling nozzles

37

•

Free space for the conveying system 80 mm

Tab. 6-1: Useful cross section

With the useful cross section of the storeroom, the

storage volume and the storage contents can be

calculated:

•

Storage volume (in m³) = useful cross section (m²)

x room length

•

Amount (in tonnes) = storage volume (m³) x 0.650

6.4

Filling nozzles

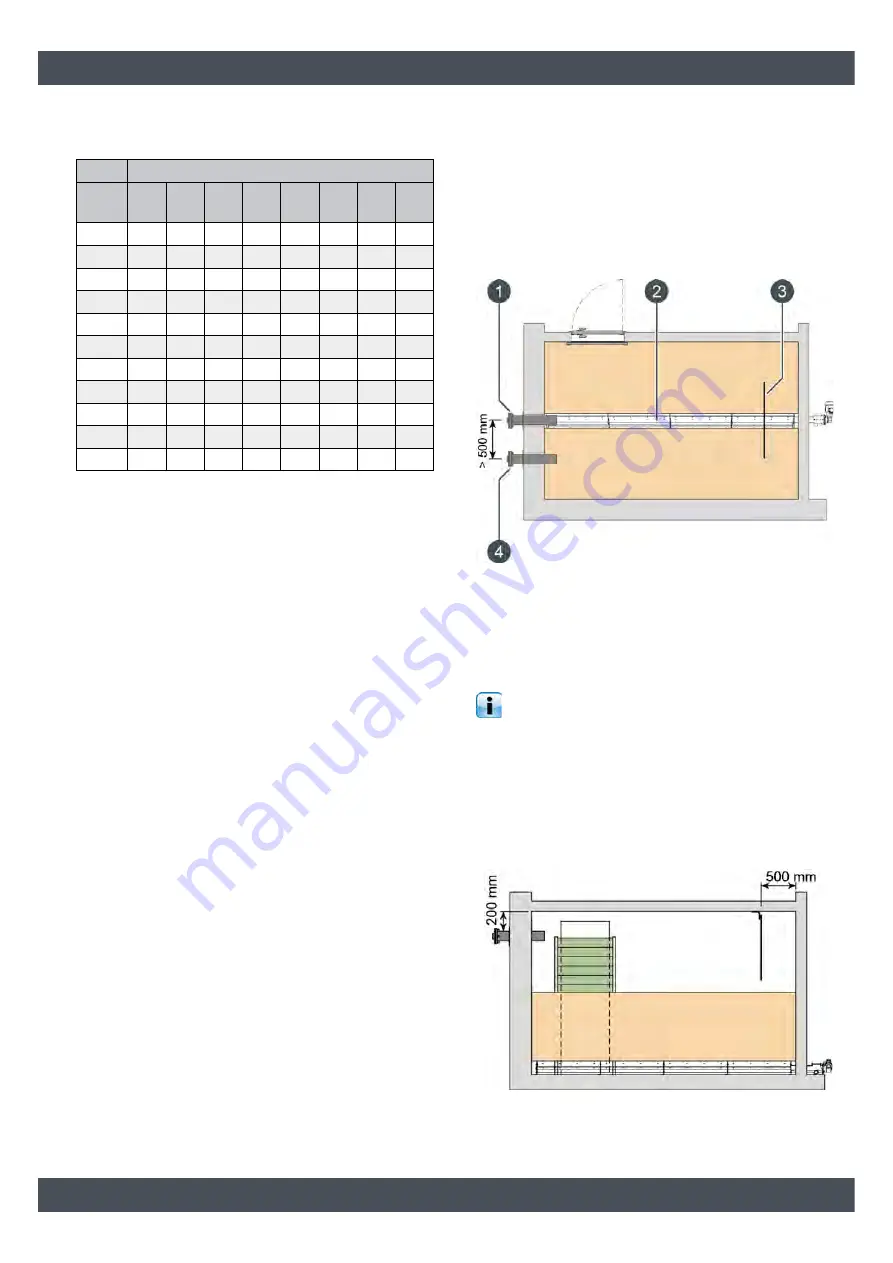

Installing the filling nozzles in the narrow side of

the pellet store

Two nozzles are preferably installed in the narrower

outer wall of the pellet store. One for blowing in the

pellets (filling nozzle) in the middle and the other for

back air (back air nozzle) to the side.

Fig. 6-2: Filling nozzles on the short side

1

Filling nozzle

2

Conveyor screw

3

Impact protection mat

4

Return air nozzle

Label the filling nozzle and the suction nozzle so

that the pellet supplier recognises which nozzle

the pellets are blown into.

Opposite the middle filling nozzle, an impact protection

mat is installed 500 mm from the wall to prevent

damage to both pellets and the plasterwork on the wall.

The filling nozzles must be installed 200 mm below the

ceiling to keep the pellets from scraping on the ceiling

during injection.

Usable cross section in m²

Total height of the storeroom (m)

Width

(m)

2.0

2.2

2.4

2.6

2.8

3.0

3.2

3.4

2.0

2.20 2.60 3.00 3.40 3.80 4.20 4.60 5.00

2.2

2.33 2.77 3.21 3.65 4.09 4.53 4.97 5.41

2.4

2.44 2.92 3.40 3.88 4.36 4.84 5.32 5.80

2.6

2.53 3.05 3.57 4.09 4.61 5.13 5.65 6.17

2.8

2.61 3.17 3.73 4.29 4.85 5.41 5.97 6.53

3.0

2.67 3.27 3.87 4.47 5.07 5.67 6.27 6.87

3.2

2.72 3.36 4.00 4.64 5.28 5.92 6.56 7.20

3.4

2.75 3.43 4.11 4.79 5.47 6.15 6.83 7.51

3.6

2.76 3.48 4.20 4.92 5.64 6.36 7.08 7.80

3.8

2.76 3.51 4.27 5.03 5.79 6.55 7.31 8.07

4.0

2.76 3.53 4.33 5.13 5.93 6.73 7.53 8.33