6

ASSEMBLY

VICTORY-LX 3 LEG ELECTRIC TABLE BASE

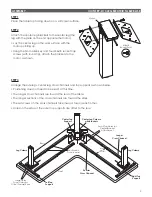

STEP 12

Attach the cross channels to the table.

• Position one U-bracket over each section of cross

channel, between the set screws, as shown (four

brackets total).

• Use the remaining M6x20 Phillips round head

screws (16 total) to fasten the U-brackets to the

work surface.

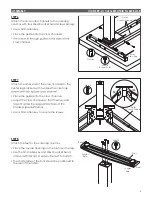

STEP 14

Attach the control unit using the two M5-15 Phillips

round head screws.

• Position the control unit near the back of the

table, on the same side as the digital keypad.

• Be sure that the cable from the keypad can reach

the control unit, and the motor cables can

extend from the control unit to all three motors.

M6x20

M5x15

Control

Unit

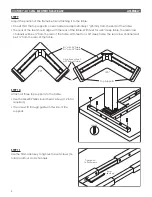

STEP 13

Attach the digital keypad using the three M3-20

Phillips round head screws.

• Position the digital keypad on the left or right side

of the table, according to user preference.

•

the table and expand to make flush. This will

prevent overhang and collision with the keypad.

Mount the keypad 1

/

”

from the front edge of

1 16

Digital

Keypad

M3x20

1

/

”

1 16

MOUNT

FROM EDGE