7

VICTORY-LX 3 LEG ELECTRIC TABLE BASE

ASSEMBLY

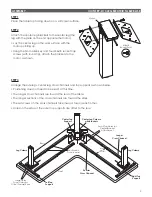

STEP 15

Make connections to the control unit and motors.

• Connect the cable from the digital keypad into

the control unit.

• Connect the motor cables from the control unit

to each of the three motors on the table legs.

• Connect the power cord to the control unit.

• Plug the power cord into an AC outlet.

CAUTION:

Do not operate the table until after

initializing the system. See following step.

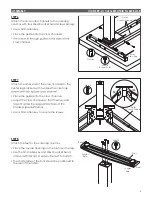

STEP 16

Initialize the system before testing operation.

IMPORTANT:

The initialization procedure below

must be completed before operating the table.

• Press and hold the UP and DOWN buttons

simultaneously for more than 3 seconds.

— The legs will begin to move down at half

speed of normal operation.

• Continue to press the UP and DOWN buttons.

— The legs will move down to the lowest position, then rebound

1

/

16

" to

3

/

16

" (2mm to 5mm) and stop.

• Release the UP and DOWN buttons at the same time. This completes the initialization procedure.

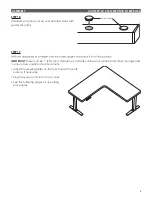

STEP 14

Test operation.

• Press the UP and DOWN buttons individually to test operation. End your test with the legs lowered

and unplug the power cord.

• If there are problems with operation, check that all cable and cord connections are secure. If problems

continue, call ESI Customer Service.

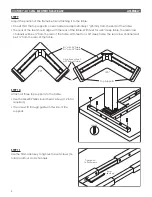

STEP 17

Use the cord clips to secure the cables and cords in position.

• Cables must not interfere with table operation.

• Cables must not interfere with the user.

•

clips to the table.

Note:

Until the table is turned

upright, the DOWN button points

up and the UP button points down.

Press and Hold

UP and DOWN Buttons

Cord Clip

M3.5x16

Digital

Keypad

Cable

Power

Cord

Motor

Cables