1

VICTORY-LX 3 LEG ELECTRIC TABLE BASE

PARTS AND TOOLS

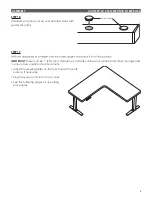

PLEASE REVIEW

these instructions before beginning the assembly procedures. Check that all the parts shown

below were provided with your order. Contact your supplier if any materials are missing. Do not discard the

your satisfaction.

ADDITIONAL TOOLS REQUIRED

•

• Power Drill (wood screws only)

Phillips screwdriver

NOTE:

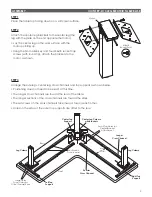

The Victory 3 Leg Electric Table Base can be used with 90° or 120° work surfaces. Assembly is the

same except for the attachment to the center leg brackets. On the following pages, the illustrations show

90° tables; 120° tables are illustrated only to show the difference in attachment to the center leg brackets.

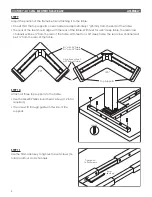

CAUTION:

Always check that screws

used to attach components to the

work surface are not too long for the

thickness of the surface.

Work

Surface

PARTS PROVIDED

Fasteners

Motor Cable (3)

Power Cable (1)

Hole Cover (26)

Left

Left

Glide

Left

Right

Right

Short

Short

Long

Long

Right

Center

M6x18 (14)

Socket Cap

Round Point

Top Supports (3)

U-Bracket (8)

Cord Clip (12)

5mm Allen Key (1)

Center Leg Brackets (2)

Side Legs with

Motor (2)

Center Leg with

Motor (1)

Cross Channels (4)

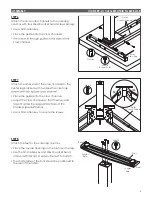

CAUTION:

Hand-tighten screws only.

Digital Keypad (1)

Control Unit (1)

Feet (2)

Guides (8)

M5x15 (2)

Round Head

M3x20 (3)

Round Head

M6x20 (28)

Round Head

M3.5x16 (12)

Flat Head

M6x15 (12)

Socket Cap