EZ 1000 Series II Melter Part Manual

Chapter 6 Maintenance Instructions

©2019 by Crafco, Inc. All Rights Reserved……………..…………………………………..….…Maintenance Instructions 6-4

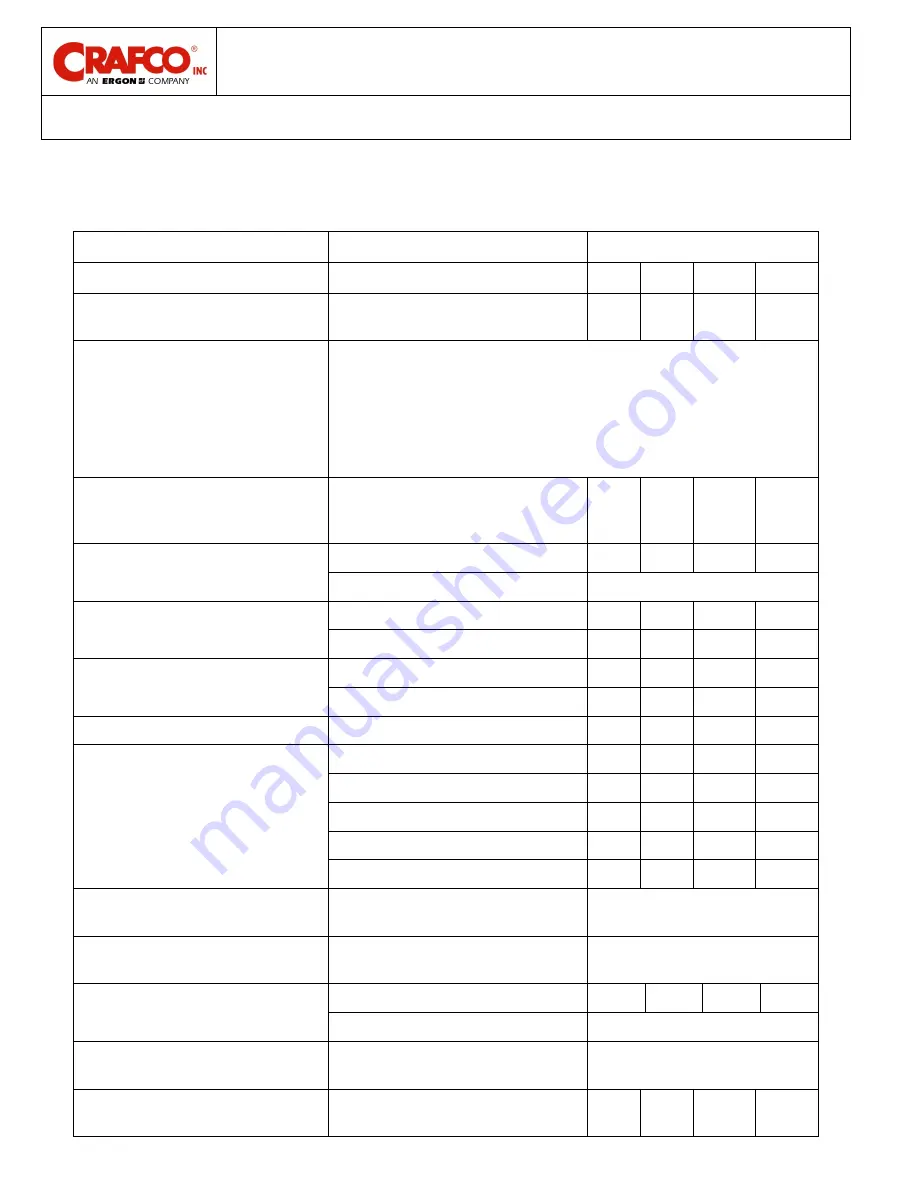

6.15 Maintenance Chart

For a list of parts required for maintenance see

Table 6-4 General Maintenance Parts

Table 6-2 Maintenance Chart

Hours

Possible Cause

Procedure

8

50

250

500

Engine check oil level

Refer to the manufacturer’s

instructions for the engine

X

Engine Air Filter(s)

Change the Primary filter when restriction indicator says to.

Safety filter is there to protect engine if main filter becomes

damaged and then the safety will see an increase in dust. Check

the safety filter when changing the primary filter, if it shows

excessive dirt or the restriction indicator is still high after

servicing the primary filter then the safety filter needs to be

changed.

Other engine maintenance

Refer to the manufacturer’s

operating and maintenance

instructions for the engine

Material Sensor Tube

Check for HTO fluid

X

Add

As needed

Heat Transfer Oil

Check

X

Change

X

Hydraulic Oil

Check

X

Change

X

Hydraulic Oil Filter

Change

X

Burner

Check burner box insulation

X

Clean CAD cell

X

Check Electrodes

X

Check Flame Retainer/Head

X

Replace burner nozzle

X

Wheel Bearings

Clean and re-pack using a good

grade of bearing grease

Every 24,000 miles or two

years

Tongue Jack

Grease using a good grade of

bearing grease

Once a year

Air Compressor Oil

Check

X

Change

Once a year

Material Tank

Scrape out built up material in

the material tank

Once a year or as needed

Material Sensor Guard

Scrape out built up material

around guard

X

Summary of Contents for Crafco 46200EB

Page 1: ...Parts Manual 26458 Revision Q ...

Page 16: ......

Page 18: ......

Page 26: ......

Page 48: ......

Page 66: ......

Page 196: ......

Page 200: ......

Page 201: ......

Page 202: ... 2019 Crafco Inc ...