EZ 1000 Series II Melter Part Manual

Chapter 6 Maintenance Instructions

©2019 by Crafco, Inc. All Rights Reserved……………..…………………………………..….…Maintenance Instructions 6-1

6.0 Maintenance Instructions

This chapter contains all normal maintenance instructions to properly maintain your machine.

6.1 Engine

Refer to the manufacturer’s operating and maintenance instructions for the engine.

6.2 Air Compressor

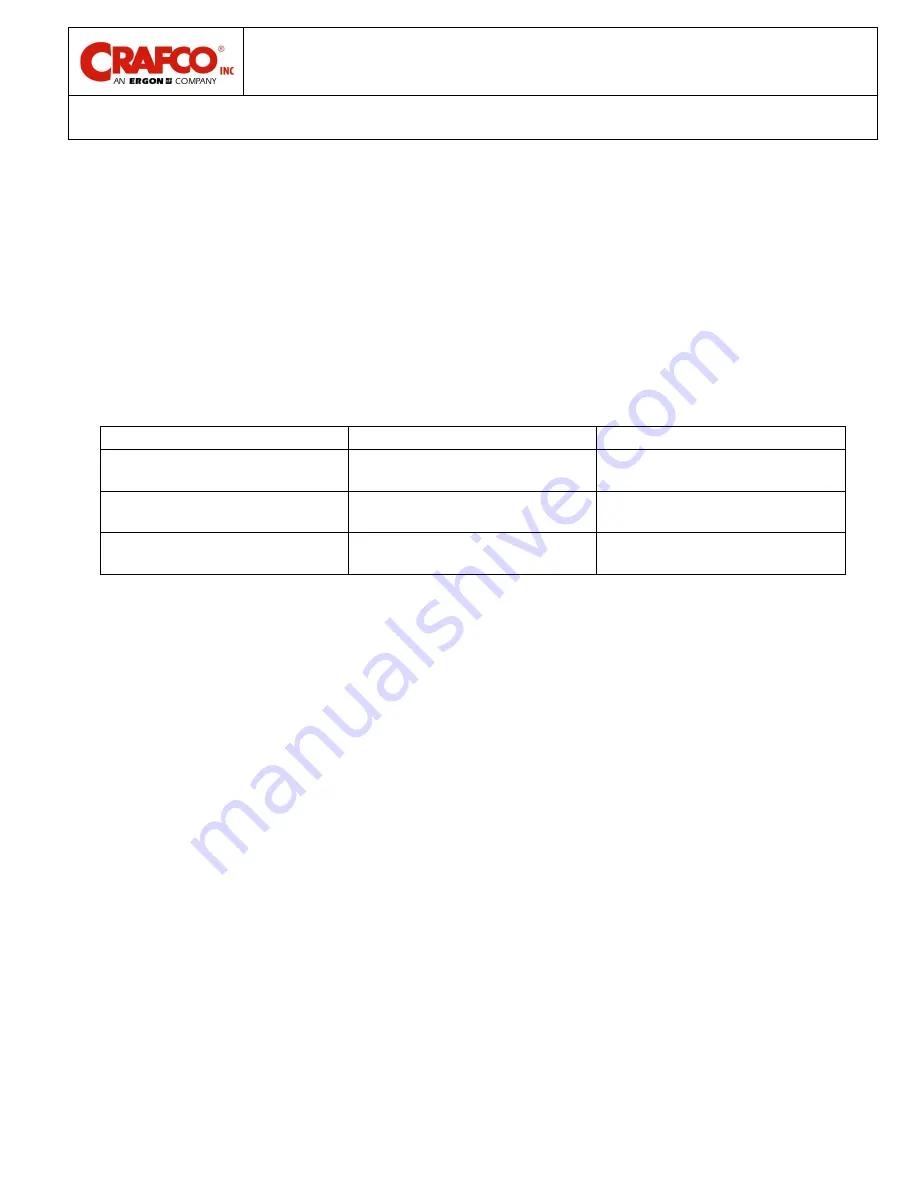

Table 6-1 contains the recommended service intervals for the air compressor, as well as the part

numbers for the maintenance kits. Also refer to the manufacturer’s operating and maintenance

instructions for the air compressor.

Use Every

Kit Description

Part No.

2500 Hrs.

Maintenance Kit A, Air filter

service kit

45328A

5000 Hrs.

Maintenance Kit B, Oil filter

service kit

45328B

10,000 Hrs.

Maintenance Kit C, Separator

Service Kit

45328C

6.3 Hydraulic System

Check hydraulic fluid daily. See

Table 5-1 Preparing the Machine for Start Up

Change hydraulic filter every 250 hours of machine operation. Replace if necessary.

Change hydraulic fluid every 500 hours of operation.

6.4 Heat Transfer Oil

Check the oil level at the start of every day. See

Table 5-1 Preparing the Machine for Start Up

Step

4.

Change the oil every 500 hours of machine operation or 1 year, whichever comes first. Failure to

follow this oil change interval will result in machine damage.

6.5 Wheel Bearing

Pack the wheel bearing every 24,000 miles (38,624 km) or every two years, whichever comes first.

Use a good grade of bearing grease.

6.6 Material Sensor Tube

Check for heat transfer oil in tube every 50 hours of operation. 2 ounces (59.1 ml) required.

Table 6-1 Air Compressor Maintenance Chart

Summary of Contents for Crafco 46200EB

Page 1: ...Parts Manual 26458 Revision Q ...

Page 16: ......

Page 18: ......

Page 26: ......

Page 48: ......

Page 66: ......

Page 196: ......

Page 200: ......

Page 201: ......

Page 202: ... 2019 Crafco Inc ...