EZ 1000 Series II Melter Part Manual

Chapter 5 Operating Instructions

©2019 by Crafco, Inc. All Rights Reserved………………..…………………………………..….Operating Instructions 5-7

5.4 Altitude Compensation System (46200EB, 46200SB Only)

This unit may be equipped with an Altitude Compensation System. If so, there will be a small boxed

housing mounted to the right and aft of the engine. The system is automatic during most operating

conditions. However, if the machine is taken from above or below an altitude of 2,624 ft. (800

Meters) while the engine is running, the engine will need to be stopped and then restarted. There is

a yellow indicator light that illuminates when the machine is above 2,624 ft. (800 Meters) indicating

that the system is active.

5.5 About the Heated Hose, Wand, Valve, and Tip Guard

The Heated Hose

The heated hose supplied with the machine is Teflon-lined with steel over braid. It has a heating

element, which runs the length of the hose to heat the material within the hose. The hose is

covered with high temperature, durable rubber.

The Wand

The wand has an aluminum tube to protect both the wand and the operator. The pistol grip actuator

is equipped with an electric switch which, when depressed, sends a signal to actuate the pump.

The wand is equipped with a trigger lock to prevent accidental pump actuation when it is not

pumping material.

The trigger must be in the “LOCKED” position at all times except when

intentionally pumping material.

The Valve

The wand has a disposable duckbill valve on the end, which shuts off the flow of material when the

pump is turned off and prevents excessive dripping of material. This valve also directs the material

into a stream for easy application into the crack. Other sealing tips are available. See

for other sealing tips and options.

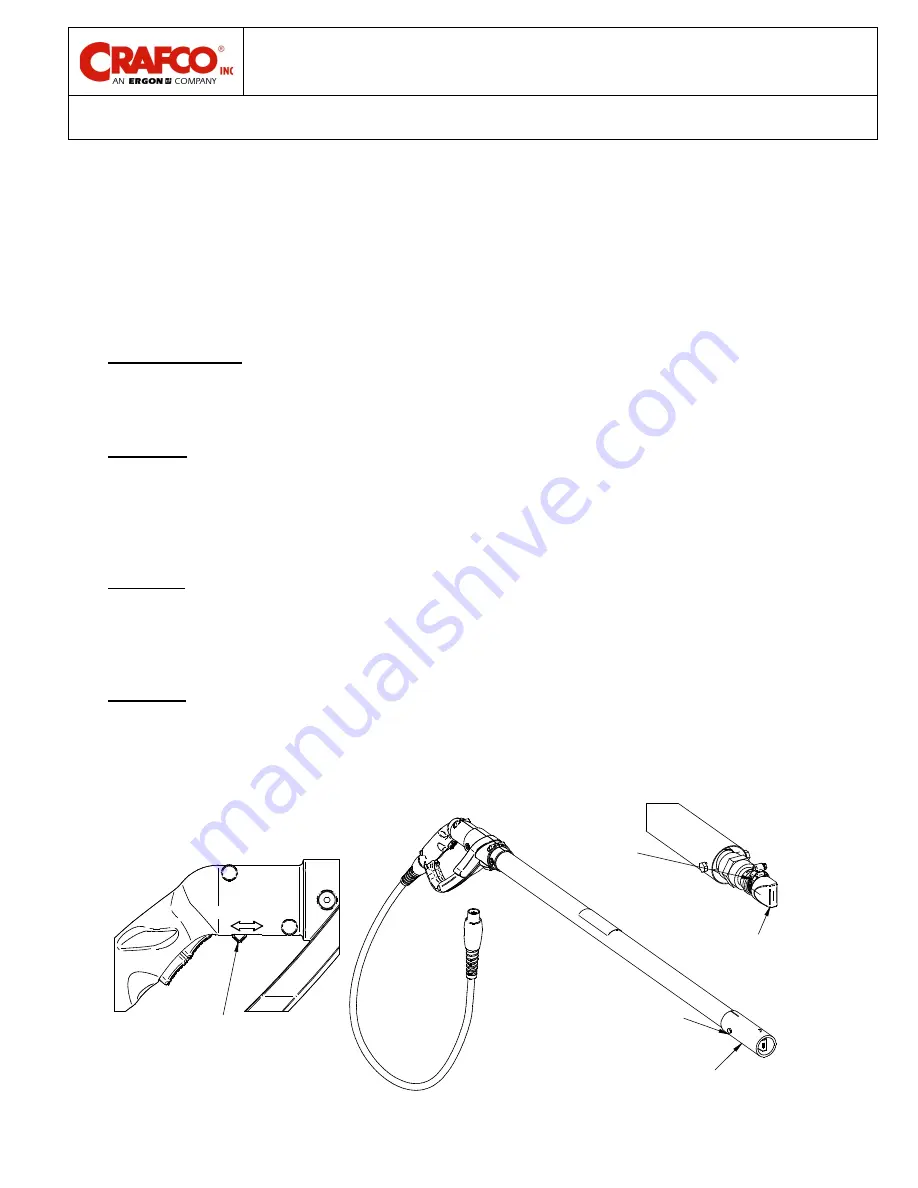

Tip Guard

The wand has a Tip Guard installed at the factory only when a duckbill is installed. This Tip Guard

is not required when using sealing disk or dripless tip adapter. The purpose of this guard is to

prolong the life of the duckbill and to protect the operator in the event of a duckbill failure. Ensure

this guard is installed properly before operating equipment. See below.

50270

50278

TIP GUARD IS

HELD IN PLACE

WITH 2 BOLTS

TRIGGER LOCK

MAKE SURE TRIGGER LOCK IS

ENGAGED AT ALL TIMES EXCEPT

WHEN APPLYING MATERIAL!

LOCKED UNLOCKED

INSTALL 26084 MINI

GEAR CLAMP ONTO

THE DUCKBILL VALVE

Summary of Contents for Crafco 46200EB

Page 1: ...Parts Manual 26458 Revision Q ...

Page 16: ......

Page 18: ......

Page 26: ......

Page 48: ......

Page 66: ......

Page 196: ......

Page 200: ......

Page 201: ......

Page 202: ... 2019 Crafco Inc ...