Correcting the print

misalignment

A small distance between the print head and the T-shirt

may cause ink misalignment due to the temperature,

humidity, inertial force of the print head's movements,

direction of the print head's movement (right to left and

left to right), and thickness and texture of the media. Ink

misalignment can also occur if the platen feed varies for

some reason. This may produce grainy or blurry results.

Adjust the printer to correct the misalignment.

The following two options are available for correcting

print misalignments.

❏

Head Alignment (when there are vertical lines or

faint text)

❏

Offset Head Alignment (when you want to fine tune

after performing Head Alignment)

❏

Feed Adjustment (when there are horizontal lines)

This section explains how to visually check the check

pattern and use

Head Alignment

to perform

corrections. See the following for more details on

Offset

Head Alignment

and

Feed Adjustment

.

U

Head Alignment

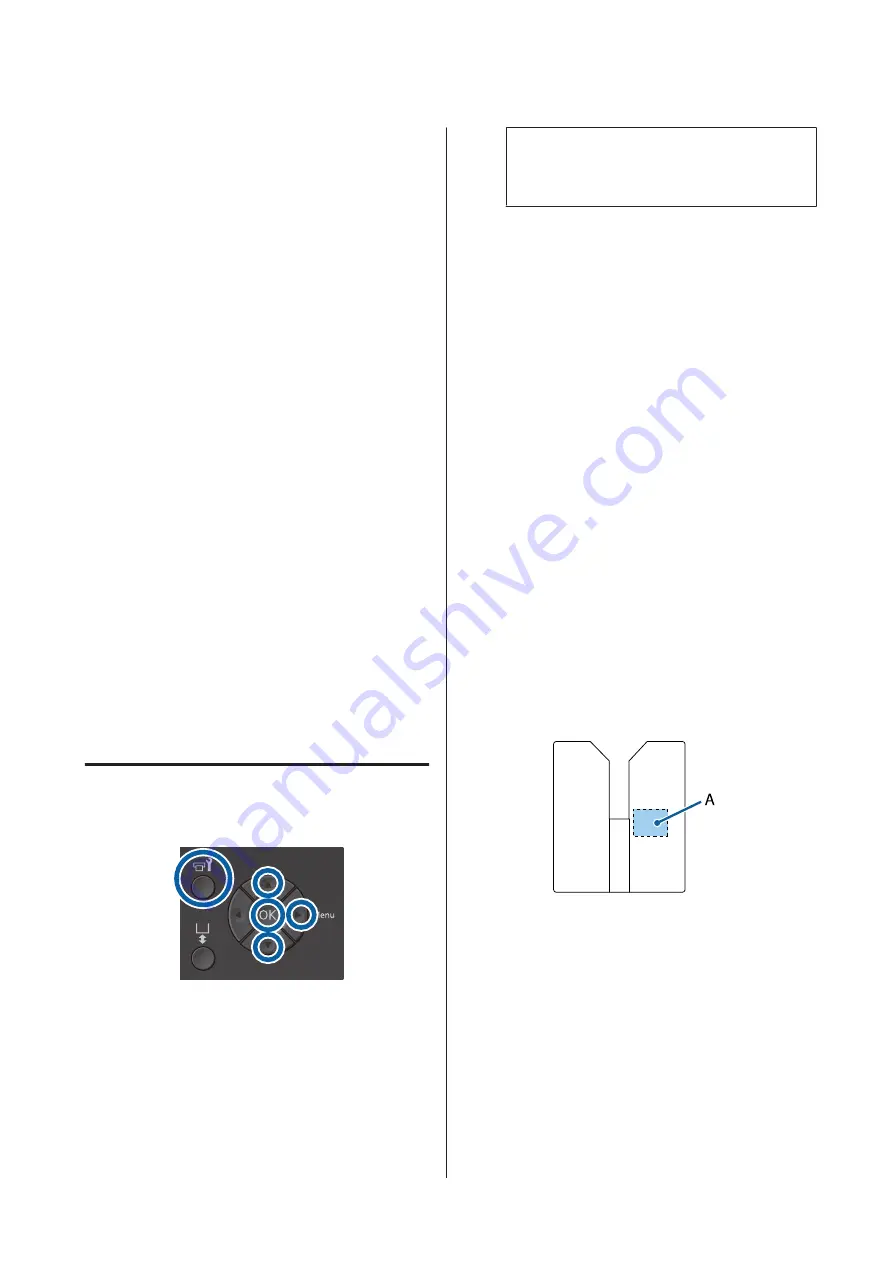

Buttons that are used in the following operations

A

Load the T-shirt for which you want to perform

adjustments on the platen, and then adjust the

height by moving the platen gap adjustment

lever.

U

“Load the T-shirt (media)” on page 45

Note:

The check pattern is printed at the same size as the

top surface of the platen installation plate.

B

Press the

r

button to display the Settings menu.

C

Press the

u

/

d

buttons to highlight

Printer

Setup

, and then press the

r

button.

D

Press the

u

/

d

buttons to select

Head

Alignment

, and then press the

r

button.

E

Press the

u

/

d

buttons to highlight the size of the

installed platen, and then press the

r

button.

F

Press the

Z

button.

G

Check that T-shirt is loaded, and then press the

Z

button again.

The check pattern is printed.

When printing a head alignment check pattern

with platens other than medium grooved platen,

the range of the check pattern that is printed is

about the same size as the top surface of the

platen installation plate.

When printing with medium grooved platen, it

will be similar to the following diagram.

A: Print check pattern range

SC-F2100 Series User's Guide

Maintenance

82