Connecting the Printer to Your Computer

If the self test printed correctly, you are ready to connect your

printer to the computer. Most computers have a parallel interface.

To connect such an interface, use a suitable shielded cable as

described in the next section.

The parallel interface

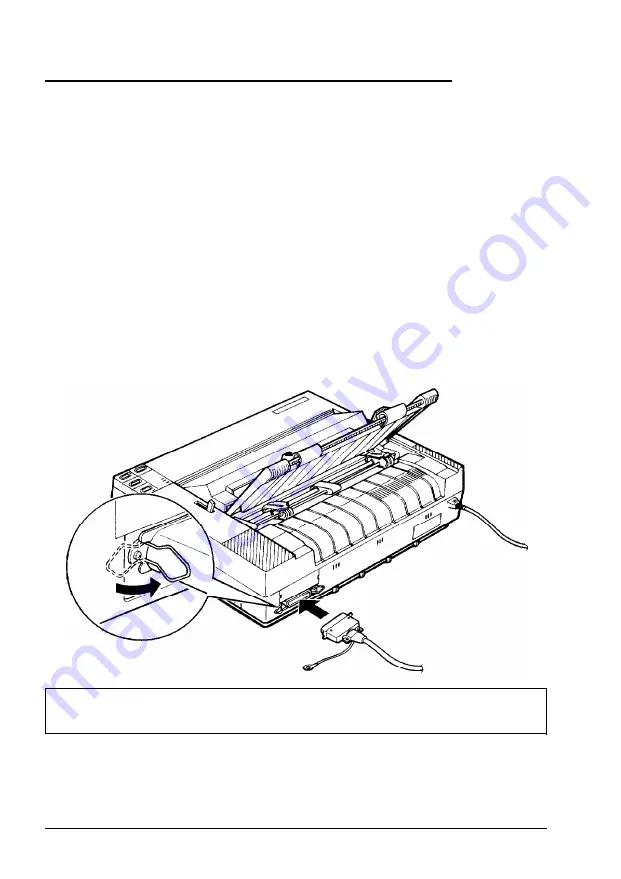

Connect the parallel interface cable as described below:

1.

Make sure

that

both your printer and computer are turned off.

Plug the cable connector securely into the printer. Then

squeeze the wire clips together until they lock in place on

either side of the connector.

Note: If your cable has a ground wire, connect it to the ground

connector beneath the interface connector.

2.

Plug the other end of the cable into the computer. (If there is a

ground wire at the computer end of the cable, attach it to the

ground connector at the back of the computer.)

Setting Up the Printer

1-13